LAB REPORT

Science and Technology Making Headlines

June 3, 2016

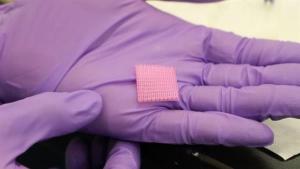

A sponge-like material containing a baking soda ingredient is being tested as a means of capturing carbon.

Saving the world with baking soda

Lawrence Livermore scientists are testing sponges made with the key ingredient of baking soda as a way of capturing carbon emissions.

The researchers say that baking soda is more effective than current methods and less damaging to the environment. The team has successfully tested microcapsules filled with the substance.

They believe that the baking soda approach could be 40 percent cheaper than existing technology.

"Sometimes the solutions have been sitting right in front of you for a very long time," said LLNL’s Joshua Stolaroff. "And we think there is great promise that baking soda might save the world."

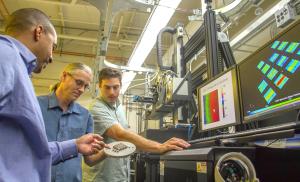

Ibo Matthews, Gabe Guss and Phil Depond examine an additively manufactured (AM) set of metal test cubes using a newly acquired laser-based powder bed fusion R&D. Photo by Julie Russell/LLNL

One step beyond

Researchers at Lawrence Livermore National Laboratory have taken a major step toward answering a question plaguing a common metal 3-Dprinting technique: What interactions can lead to the porosity found in parts produced by laser powder-bed fusion processes?

In recent research, LLNL scientist Ibo Matthews and his team discovered that gas flow, due to evaporation when the laser irradiates the metal powder, is the driving force that clears away powder near the laser’s path during a build. This phenomenon reduces the amount of powder available when the laser makes its next pass, causing tiny gaps and defects in the finished part.

“During this process you get to temperatures that are near or at the boiling point of the metal, so you have a strong vapor flux emitted from the melt pool,” Matthews explained. “Prior to this study, there wasn’t an understanding of what effect this flux of metal vapor had on the powder bed.”

LLNL engineer Vanessa Tolosa holds up a flexible electrode array that gets implanted into animals to record brain signals. Photo by Julie Russell/LLNL

Better tools for the brain

Five years ago, Vanessa Tolosa wasn’t sure how she would get funding to support her brain research.

The chemical engineer at Lawrence Livermore National Laboratory had finished an artificial retina research project but had no prospects for more funding. “On the technology side, it’s actually difficult to get funded” by the federal government, she says.

That is until the White House announced the Brain Research through Advancing Innovative Neurotechnologies (BRAIN) Initiative in 2013. Now Tolosa works on a half-dozen projects that use her chemical engineering skills toward the initiative’s goal of creating tools to better study the brain.

No one knows how many chemists and chemical engineers are involved in the BRAIN Initiative, but they are few and far between, Tolosa says. She is excited to hear that agencies are reaching out. “I think we have a unique contribution we can provide to the community,” she said.

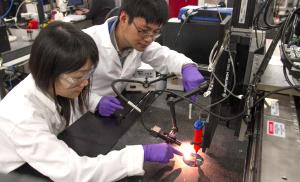

LLNL material and biomedical scientist Fang Qian (left) and engineer Cheng Zhu demonstrate a direct-ink writing 3-D printer they used to manufacture supercapacitors out of a graphene-based aerogel. Photos by Julie Russell/LLNL

Batteries be gone

The common battery may not keep going and going after all. Lawrence Livermore engineers made the first successfully 3-D printed supercapacitors using an ultra-lightweight graphene aerogel that could lead to the end of batteries as the universal power source.

Batteries power everything from cellphones to automobiles. They also get shipped by the tons to combat theaters, take up space in tactical vehicles and are carried across the battlefield on the backs of warfighters who are already overloaded with equipment.

By comparison, supercapacitors store vast amounts of energy. Commercially available supercapacitors recover braking energy in cars, buses and trains and open the emergency exits of the Airbus A380. Supercapacitors can charge incredibly quickly, potentially requiring just minutes or seconds to reach full capacity, said Cheng Zhu, a Lawrence Livermore National Laboratory engineer.

Refueling of the High Flux Isotope Reactor at Oak Ridge National Laboratory (ORNL). Antineutrinos are emitted from the decays of the fission products. Image by Genevieve Martin/Oak Ridge National Laboratory.

A PROSPECTive search

With a new grant, Lawrence Livermore and Oak Ridge national laboratories, along with Yale University, will participate in an experiment that will explore key questions about the elusive particles called neutrinos — and potentially improve the way the country monitors and safeguards nuclear reactors in the process.

The Department of Energy $3 million grant from the Office of High Energy Physics will be used to build a first-of-its-kind, short-distance detection device for the Precision Oscillation and Spectrum Experiment (PROSPECT), a project involving 68 scientists and engineers from 10 universities and four national laboratories.

The PROSPECT experiment has been in development for more than three years.

“Drawing on our extensive expertise in neutrino physics, liquid scintillator development and reactor monitoring applications, PROSPECT has a mature, construction-ready system design that will result in a world-leading measurement,” said Nathaniel Bowden, co-spokesperson for PROSPECT and a physicist at Lawrence Livermore.