LAB REPORT

Science and Technology Making Headlines

July 8, 2016

A team of scientists and engineers at Lawrence Livermore National Laboratory is developing “human-on-a-chip,” a miniature external replication of the human body. Photo by Julie Russell/LLNL

Goodbye lab rat?

The lab rat may be out of job.

Developing new prescription drugs and antidotes to toxins currently relies extensively on animal testing in the early stages. That is not only expensive and time consuming, but it also can give scientists inaccurate data about how humans will respond to such agents.

But what if researchers could predict the impacts of potentially harmful chemicals, viruses or drugs on human beings without resorting to animal or even human test subjects?

To help achieve that goal, scientists and engineers at Lawrence Livermore are developing a “human-on-a-chip,” a miniature external replication of the human body, integrating biology and engineering that would eliminate the need for animal testing.

Lawrence Livermore National Laboratory's high performance computing capabilities play a major role in the Cancer Moonshot initiative. Image courtesy of Washington University School of Medicine in St. Louis.

Data sharing in a fight for the cure

As part of his Cancer Moonshot, Vice President Joe Biden has announced several new data-sharing initiatives to double the rate of progress in the fight against cancer.

The Cancer Moonshot is aimed at making more therapies available to more patients, while also improving the nation’s ability to prevent cancer and detect it in an early stage.

The Department of Energy, in partnership with the National Cancer Institute, is launching three new pilot projects focused on bringing together nearly 100 cancer researchers, care providers, computer scientists and engineers to apply the nation's most advanced supercomputing capabilities to analyze data from preclinical models in cancer, molecular interaction data and cancer surveillance data across four DOE national laboratories, including Lawrence Livermore.

LLNL and Kansas State University researchers are tracking down the spread of swine viruses.

It’s a pig’s life

Researchers in the College of Veterinary Medicine at Kansas State University have teamed up with Lawrence Livermore to evaluate the impact and association of microbiomes connected with two of the most devastating viral diseases in swine.

The work was published in the May 2016 issue of Veterinary Microbiology.

The term microbiome refers to the community of microorganisms living in or on the surface of our bodies. The gastrointestinal tract houses the greatest proportion of these microorganisms.

The porcine reproductive and respiratory syndrome virus and porcine circovirus type 2 have caused billions of dollars in losses to swine producers over the last 25 years.

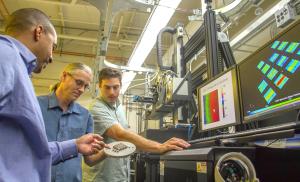

Ibo Matthews, Gabe Guss and Phil Depond examine an additively manufactured (AM) set of metal test cubes using a newly acquired laser-based powder bed fusion R&D platform. Photo by Julie Russell/LLNL

A look inside 3-D printing

A Lawrence Livermore team has uncovered a major issue plaguing a common metal 3-D printing technique: defects and roughness in additive manufactured metal components. The new discovery could lead to a faster adoption of 3-D printing than previously anticipated.

When the additive manufacturing project began, LLNL scientist Ibo Mathews hinted that Lawrence Livermore should expect groundbreaking results, explaining the team plans to do more detailed experiments on metal-based additive manufacturing than what has been done before. This latest research represents new insights into the prediction and minimization of void defects and surface roughness in additively manufactured metal components.

The rapid heating and high temperatures generated using lasers for additive manufacturing with metal is known to improve part strength. But the same process also can result in voids or pores, and this can weaken such parts. These defects arise when there is incomplete melting of metal powder or if strong vaporization causes, “keyhole-mode melting.”

LLNL researchers are using sodium bicarbonate, or baking soda, to absorb carbon dioxide.

Wash that carbon right out of the air

Joshua Stolaroff, an environmental researcher at Lawrence Livermore, thinks that baking soda might save the world. Baking soda can be used to eliminate harsh chemical cleaners and can clean almost everything, even clogged drains.

But Stolaroff and his colleagues believe that the inexpensive household substance could go even further toward saving the environment by actually capturing and storing carbon emissions.

Scientists have been working for years to develop an effective method of trapping the carbon dioxide emitted from power plants (carbon capture and storage). But the high cost of the equipment and chemicals needed to trap such a large amount of CO2 has made little progress.

A team at Lawrence Livermore is trying to change that. The researchers have developed microcapsules filled with a liquid solution of sodium carbonate encased in a polymer shell that allows carbon dioxide to flow through. When the sodium carbonate comes into contact with carbon dioxide and water, it creates sodium bicarbonate, aka baking soda — a cheap, non-toxic carbon absorber.