LAB REPORT

Science and Technology Making Headlines

Sept. 16, 2016

Glendon Parker, a biochemist with Lawrence Livermore National Laboratory’s Forensic Science Center, examines a 250-year-old hair sample that has been analyzed for human identification using protein markers from the hair. Photo by Julie Russell/LLNL

Hairprints instead of fingerprints

Proteins in your hair could identify you at a crime scene. It may even replace DNA sequencing in forensic investigations.

Lawrence Livermore National Laboratory researchers have demonstrated a method to extract genetic information from proteins found in hair that is remarkably reliable. “Currently forensic science is very dependent on DNA,” says lead scientist Glendon Parker, a biochemist at Livermore. “But analyzing proteins can add information that can help make a case stronger.”

DNA breaks down pretty quickly when it’s not inside living cells. And as hair grows, the cells that make up the hair shaft die off because they get stretched and move further away from their supply of nutrients. The only DNA that can survive inside hair is hidden away in mitochondria, and it doesn’t contain all the information that DNA from the cell’s nucleus would have. Proteins, on the other hand, are more stable than DNA and are more abundant in hair.

Much like a slinky that springs back to its original shape, LLNL researchers have found that iron can do the same thing when compressed.

Springing back to shape

A team of Lawrence Livermore National Laboratory physicists has performed a series of calculations shedding light on an unexpected way that iron transforms under dynamic compression.

The team describes first-principle calculations on two solid phases of iron, as well as on intermediate crystal structures along the transformation path from one phase to the other. The calculations involve a carefully parameterized model for magnetic fluctuations, including the effect of moving the iron nuclei as the material is squeezed in a shock experiment.

Lawrence Livermore scientists have played multiple roles in this particular problem, spanning more than a decade. A Laboratory Directed Research and Development Strategic Initiative project performed pioneering shock experiments, including some on single crystal iron.

This fast, reversible transition was actually predicted by large-scale molecular dynamics (MD) simulations, but neglected the role of magnetism. Yet, more accurate, first-principle, magnetic calculations performed for iron by LLNL implied much slower transformations.

By using high performance computing combined with advanced manufacturing and additive manufacturing, researchers can design and build new devices and materials with unique physical and microstructural properties.

Jump starting energy efficiency

The Department of Energy’s (DOE) High Performance Computing for Manufacturing program, designed to spur the use of national lab supercomputing resources and expertise to advance innovation in energy efficient manufacturing, is seeking a new round of proposals from industry to compete for $3 million.

The High Performance Computing for Manufacturing (HPC4Mfg) program supports 29 projects partnering manufacturing industry members with DOE national labs to use laboratory HPC systems and expertise to upgrade their manufacturing processes and bring new clean energy technologies to market. This is the third round of funding for this rapidly growing program.

The partnerships use world-class supercomputers and the science and technology expertise resident at Lawrence Livermore National Laboratory, which leads the program, and partner laboratories Lawrence Berkeley and Oak Ridge national laboratories. An HPC expert at each lab teams up with U.S. manufacturers on solutions to address challenges that could result in advancing clean energy technology.

A single chain of water molecules lines the cavity inside a carbon nanotube porin, which is embedded in a lipid bilayer. Image by Y. Zhang and Alex Noy/LLNL.

Water flows fast and furious

The movement of protons — hydrogen atoms with the electrons stripped away — through a membrane is critical to efficiently producing electricity in a fuel cell. A decade ago, theory predicted that confinement of water into a single one-dimensional chain would achieve rapid proton transport, with the protons hopping down the chain of hydrogen-bonded water molecules.

Now tiny (less than a nanometer in diameter) carbon nanotubes that confine water into one-dimensional wires have validated this prediction of rapid proton transport and achieved rates an order of magnitude faster than protons in bulk water and faster than state-of-the-art fuel cell membranes.

Scientists at Lawrence Livermore National Laboratory and the University of California-Merced have prepared short carbon nanotubes with two different diameters embedded in synthetic lipid membranes that mimic biological ion channels.

When the diameter was greater than 1 nanometer, water was not confined to one dimension and, in this case, proton transport rates were comparable to bulk water. However, when much narrower (0.8-nanometer-diameter) tubes were used, the confined water formed one-dimensional water wires that drastically boosted the proton transport rate.

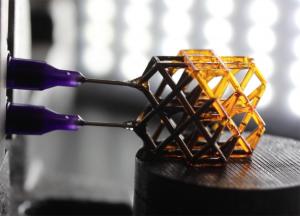

A 3D rendering of a network of hierarchical fractal-like metamaterials. Image by Ryan Chen/LLNL.

3D printing goes tiny

U.S. government labs have become involved in 3D printing in a big way by adopting the technology for research and development purposes since the technology's inception, but also pushing the boundaries of what 3D printing is truly capable of.

Lawrence Livermore National Laboratory is taking 3D printing down to the micro- and nanoscale, manipulating the physical properties of objects by modifying their inner geometries.

By 3D printing complex lattice structures at the microscale, for instance, it's possible to design parts that are extremely lightweight, but which have enormous strength due to the way that geometries of the objects behave on the microscale. Voids allow the prints to have a reduced mass, while the integrity of the microstructures maintains stiffness and strength.