LAB REPORT

Science and Technology Making Headlines

March 17, 2017

More than 60 movies of nuclear tests are now available for public viewing.

Nearly lost is now found

After decades in their film cans, thousands of nuclear testing explosion films are finally seeing the light of day, thanks to Lawrence Livermore National Laboratory scientists. Between 1945 and 1962, the United States conducted more than 200 nuclear tests up high in the atmosphere to learn about the power of nuclear weapons. The explosions were filmed from every possible angle and distance, and the movies — an estimated 10,000 of them — were then stored in high-security vaults scattered across the country.

Now, for the first time, about 4,200 of the films have been digitized by LLNL scientists and around 750 have been declassified by the U.S. government. You can watch about 60 of them on YouTube. Some are in color, some in black and white, and all of them bear the names of top secret missions: Operation Hardtack, Operation Plumbbob, Operation Teapot.

The project is spearheaded by LLNL weapon physicist Greg Spriggs, who says the project came just in time because the aging films were decomposing "to the point where they'll become useless."

Spriggs hopes to help other nuclear weapon physicists learn more about nuclear explosions.

LLNL and U.S. Navy Metalworking Center researchers are studying ways to reduce the high cost of inspecting welds on nuclear‐powered submarines.

Keeping subs ship-shape

Lawrence Livermore researchers are joining forces with the U.S. Navy Metalworking Center to study ways to ensure that welds on submarines are free of defects and hold tight.

LLNL entered a feasibility study agreement with the Navy to look at developing a non-destructive technology that can essentially peer through the submarine's coating — known as special hull treatment — to find defects in the ship's welds. Currently, hull inspections require the removal and reinstallation of the coating to examine the structure underneath, which is a costly and time-consuming process.

Lawrence Livermore Materials and Engineering Section Leader Karl Fisher said researchers will be looking at using acoustical structural excitation along with ultra-wide-band radar technology, which has proven useful in penetrating underground to search for improvised explosive devices. While Fisher cautioned the technology isn't guaranteed to work on submarines, it could help narrow the area where a crack or defect in the welding has occurred.

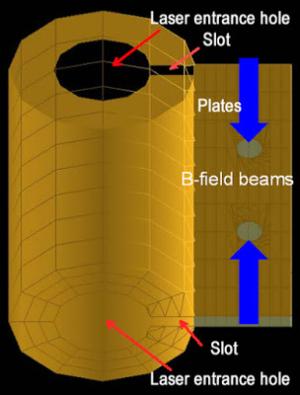

Diagram of a NIF hohlraum “loop” target modified for magnetic-field experiments. One to three NIF beams will be directed to the plates, or fins, on the side of the hohlraum to generate the magnetic fields.

Magnetic fields let it burn

Lawrence Livermore researchers are developing a new technique for creating powerful magnetic fields inside National Ignition Facility (NIF) hohlraums. Simulations and experiments have shown that magnetized hohlraums could significantly enhance NIF’s implosion performance.

The first experiments aimed at testing the technique, which uses lasers to generate the magnetic field, were conducted recently during a week devoted to discovery science experiments on NIF.

Calculations show that magnetic fields can help enhance the fusion burn rate in inertial confinement fusion (ICF) ignition targets in two ways: by reducing heat conduction away from the compressed high-temperature plasma fuel in the central “hot spot” of the target capsule; and by adding confinement to the charged particles, known as alpha particles, produced by the fusion reactions. Keeping the particles closer to the hot spot would help increase the energy deposited in the cold outer layers of fuel surrounding the hot spot — a process known as alpha heating — and thus increase the odds of generating a self-sustaining fusion reaction.

Researchers are striving to make more human brain-inspired supercomputers.

The brains behind the computer

If you have used your cellphone’s GPS to help find your way or take advantage of its translation or speech-to-text programs, then you have benefited from a deep learning neural network architecture. Inspired by the human brain’s ability to learn, deep learning neural networks are based on a class of machine algorithms that can learn to find patterns and closely represent those patterns at many levels.

Improvements in computational energy efficiency and throughput are being realized in neurosynaptic or cognitive neural network architectures. A great example of this is the Lawrence Livermore National Laboratory and IBM Research collaboration to build a new brain-inspired supercomputer. The hardware and software ecosystem is based on IBM’s breakthrough neurosynaptic computer chip called TrueNorth.

Lawrence Livermore has been testing the scalable platform and has noted that TrueNorth processes the equivalent of 16 million neurons and 4 billion synapses and consumes the energy equivalent of a hearing-aid battery. The TrueNorth ecosystem encompasses multiple-chip machines that seamlessly integrate with a software language, a programming environment, an algorithm and application library and tools for neural network composition. TrueNorth is currently in use at more than 30 universities and government/corporate labs.

A carbon fiber composite ink extrudes from a customized direct ink writing 3D printer, eventually building part of a rocket nozzle.

Not your ordinary carbon fiber

Lawrence Livermore researchers have 3D printed aerospace-grade carbon fiber composites, an advance that could lead to greater control and optimization of the lightweight, stronger-than-steel material.

Carbon fiber composites are typically fabricated by winding the filaments around a mandrel, or weaving the fibers together. These methods limit finished products to either flat or cylindrical shapes. Performance concerns lead fabricators to overcompensate with material, resulting in heavier, costlier parts.

The LLNL researchers report printing several complex 3D structures through a modified direct ink writing process. They also developed and patented a new chemistry that can cure the material in seconds instead of hours, and used the Lab's high performance computing capabilities to develop accurate models of the flow of carbon fiber filaments.