LAB REPORT

Science and Technology Making Headlines

Sept. 22, 2017

Peter Kuran cut his teeth on special effects in 1977 when he worked on “Star Wars.”

Rx for visual effects

Peter Kuran cut his teeth on special effects during his first job on “Star Wars” in 1977. He has an 82-movie career in the visual effects field, but at the same time he also became an expert in film restoration and nuclear weapons tests.

Every month and a half he goes to the Bay Area to feed his working passion. He is contracted with Lawrence Livermore National Laboratory and has become an expert in restoring archival film of nuclear weapons tests. The military tested hundreds of atom bombs before tests were banned, and they photographed everything, from every angle.

In fact, Kuran won an Academy Award for figuring out how to prevent color film from fading.

"The technique was based on something I had done for 'Return of the Jedi,'" he says. In a scene of a lightsaber fight in the desert, he figured out that colors washed out. He used a yellow mat rather than a black one around the lightsabers. The technique worked on old film, too.

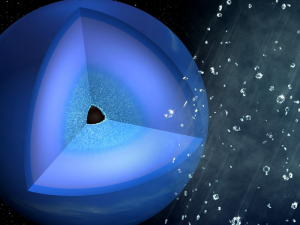

A cutaway of Neptune (left) shows the theorized interior structure of the planet, including the region where the hydrocarbon atmosphere may produce diamond rain (light blue) that falls onto the core (black center). Image by Greg Stewart/Stanford Linear Accelerator Center National Accelerator Laboratory.

It really does rain diamonds

A very hard rain likely falls inside Uranus and Neptune.

In recent high-energy laser experiments, researchers at Lawrence Livermore National Laboratory and collaborators replicated the pressures and temperatures found deep in the atmospheres of such planets, known as ice giants. Those extreme conditions in the laboratory compressed hydrocarbon plastics, chemically like the methane found in ice giants, into tiny diamonds, giving an experimental boost to a long-standing theory about the characteristics of ice giant planets.

“It was a very surprising experiment,” said Dominik Kraus, a researcher at Helmholtz-Zentrum Dresden-Rossendorf in Dresden, Germany. His team had expected very small signs of molecules splitting apart after being subjected to high pressures, “maybe some little hints of diamonds,” he explained. The idea for this experiment was born within LLNL's NIF & Photon Science Directorate, where Kraus was stationed as a University of California-Berkeley postdoc.

The team found a very strong signal that under intense pressures, hydrocarbons in Neptune would transform into diamonds.

Infectious diseases such as streptococcus may be one of the biggest public health threats.

A world at risk

As hurricanes and other natural disasters damage the world and the threat of nuclear war looms, it's hard to assess which risks for humanity are really the scariest right now.

But one of the biggest threats out there is one of the oldest: infectious disease, which can emerge naturally or be human-made, as in a case of bioterrorism.

David Rakestraw, a program manager overseeing chemical, biological and explosives security at Lawrence Livermore, and Tom Slezak, the Laboratory's associate program leader for bioinformatics, agree with Bill and Melinda Gates, who wrote in their recently released "Goalkeepers" report that disease is the biggest public health threat.

"Both natural and intentional biological threats pose significant threats and merit our nation’s attention to mitigate their impact," Rakestraw and Slezak recently said.

Lawrence Livermore researchers (from left) Ward Small, Amanda Wu and Taylor Bryson have successfully 3D printed composite silicone materials that are flexible, stretchable and possess shape memory behavior. Photo by Carrie Martin/LLNL

Making a cushier helmet

Researchers at Lawrence Livermore have 3D printed composite silicone materials that are flexible, stretchable and possess shape memory behavior. The “4D printed” materials could be used to make form-fitting cushioning for helmets, shoes and other products.

By adding hollow, gas-filled "micro-balloons" into silicone-based ink, the LLNL researchers created materials that can be “programmed” with temperature changes. The material can be squeezed into a different shape at a slightly elevated temperature, retaining that shape even after cooling.

By reheating the material, the gas in the micro-balloons expands, returning the material to its original pre-squeezing shape.

A carbon fiber composite ink extrudes from a customized direct ink writing (DIW) 3D printer, eventually building part of a rocket nozzle.

The ultimate in materials

Aerospace-grade carbon fiber could soon be available to the general public.

Lawrence Livermore researchers have become the first to 3D print aerospace-grade carbon fiber composites, opening the door to greater control and optimization of the lightweight, yet stronger than steel, material. The research represents a "significant advance" in the development of micro-extrusion 3D-printing techniques for carbon fiber.

"The mantra is 'if you could make everything out of carbon fiber, you would' – it's potentially the ultimate material," explained Jim Lewicki, principal investigator. "It's been waiting in the wings for years because it's so difficult to make in complex shapes. But with 3D printing, you could potentially make anything out of carbon fiber."

Carbon fiber is a lightweight, yet stiff and strong material with a high resistance to temperature, making the composite material popular in the aerospace, defense, and automotive industries, as well as sports such as surfing and motorcycle racing.