LAB REPORT

Science and Technology Making Headlines

Oct. 20, 2017

Beamlines entering the lower hemisphere of the National Ignition Facility’s target chamber. Lawrence Livermore researchers have successfully combined nine of the facility’s 192 laser beamlines into one directed pulse of light, nearly four times the energy of any of the individual beams. Photo credit: Damien Jemison/LLNL

Creating a ‘Death Star’ on earth

For 40 years, the Star Wars Death Star has been one of science fiction’s most iconic figures. But scientists and laser experts held that its superbeam could never work because of the properties of lasers -- theory says that the beams would just pass through one another, not converge and combine their energy.

But a team of researchers at Lawrence Livermore added a plasma -- a charged mixture of ions and free electrons -- to the concept and successfully combined several separate lasers into a superlaser.

Nine of the National Ignition Facility’s 182 lasers combined into one superbeam that is four times the energy of any of the individual beams.

Students from Livermore and Granada high schools visited the Lab on Oct. 10 to design their own cellphone speaker amplifiers as part of a Girls Who Code event. Photo by Kate Hunts/LLNL

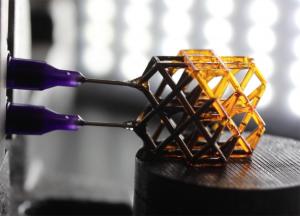

Students go 3D

It is becoming more and more apparent that 3D design and additive manufacturing should be taught in schools, to give younger generations a leg up for the future job market. For girls especially, learning about STEM (science, technology, engineering and mathematics) subjects and making them accessible at a young age can help break down barriers they might feel or face later in their lives.

It is this reality that has inspired "Girls Who Code,” a U.S.-wide nonprofit aimed at teaching students (girls especially) the basics of coding, digital design, 3D printing and more. Recently, through a collaboration with Lawrence Livermore National Laboratory and the Livermore Valley Joint Unified School District, Girls Who Code hosted a workshop in which students were invited to learn about 3D modeling and printing.

As part of the workshop, the students (including males) were tasked with designing and customizing their own cellphone speaker amplifiers using CAD programs. In the end, four lucky students (drawn from a raffle) were selected to have their designs 3D printed.

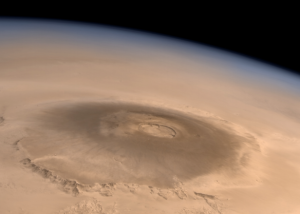

Olympus Mons on Mars is the biggest volcano in the solar system.

Revealing the red planet’s secrets

Scientists including one from Lawrence Livermore have used meteorites fallen to Earth to recreate the evolution of a volcano on Mars, in a first-ever attempt made in history.

Their conclusion: Martian volcanoes were bigger, scarier and grew a thousand times slower than those on Earth.

The space rocks hid more than 90 million years of information on the red planet's volcanoes. They allowed scientists to identify from which volcano they came from, how fast it grew and how long it was active.

Mars has the largest volcanoes in the solar system. Olympus Mons is more than 370 miles wide and over 13 miles high, more than twice the height of Mount Everest, the tallest mountain on Earth.

Tantalum crystal can flow like a viscous fluid while remaining a stiff and strong metal and retaining its ordered lattice structure. This snapshot depicts a dense network of lattice defects developing in the flowing crystal.

Jiggle and wiggle bare metal’s strength

Researchers at Lawrence Livermore National Laboratory dove down to the atomic scale to resolve every "jiggle and wiggle" of atomic motion that underlies metal strength.

In a first-of-its-kind series of computer simulations focused on the metal tantalum, the researchers predicted that on reaching certain critical conditions of straining, the plasticity (the ability to change shape under load) of tantalum meets its limits. One limit is reached when crystal defects known as dislocations are no longer able to relieve mechanical loads. This activates another mechanism -- twinning, or the sudden reorientation of the crystal lattice -- which takes over as the dominant mode of dynamic response.

“We predict that the crystal can reach an ultimate state in which it flows indefinitely after reaching its maximal strength," said Vasily Bulatov, LLNL lead of the research. "Ancient blacksmiths knew this intuitively because the main trick they used to strengthen their metal parts was to repeatedly hammer them from different sides, just like we do in our metal kneading simulation."

A new ultralight silver nanowire aerogel developed by Lawrence Livermore scientists is so light that it could lay on a fragile rosebud without the flower wilting.

New aerogel comes to light

Lawrence Livermore scientists have developed new ultra-conductive and almost-weightless silver foam that could have many applications, from energy to hardware electronics.

Researchers are working to develop ultralight and low-density materials with interesting properties for thermal insulation, acoustic damping (soundproofing), vibration or shock isolation, battery electrodes, catalytic systems, and many other applications.

The LLNL team came up with a new industrially scalable method to produce silver nanowire aerogel. They started with silver nanowire as a building block which allowed them to overcome many of the limitations of other production methods.

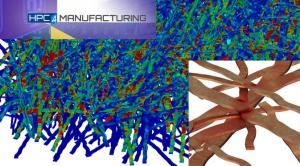

Lawrence Livermore researchers are developing a parallel program called p-fiber to help Procter and Gamble simulate the way in which paper fibers contact each other

Paper trail leads to simulations

For a large paper product manufacturer like Procter and Gamble, which regularly uses high-performance computing to develop its products, simulating the way in which those paper fibers contact each other -- is complicated and expensive. The preprocessing stage of generating the necessary computational geometry and simulation mesh can be a major bottleneck in product design, wasting time, money and energy.

To help the company speed up the development process, Lawrence Livermore National Laboratory researcher Will Elmer and his team of programmers focused their efforts on developing a parallel program called p-fiber. Written in Python, the program prepares the fiber geometry and meshing input needed for simulating thousands of fibers, relying on a meshing tool called Cubit, created at Sandia National Laboratories, to generate the mesh for each individual fiber.

The ensuing research, performed for an HPC4Manufacturing (HPC4Mfg) project with the papermaking giant, resulted in the largest multi-scale model of paper products to date, simulating thousands of fibers in ParaDyn with resolution down to the micron scale.