LAB REPORT

Science and Technology Making Headlines

Nov. 3, 2017

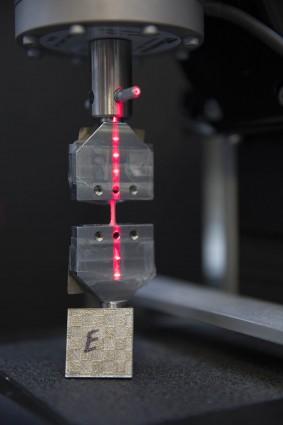

Lawrence Livermore materials scientist Joe McKeown looks on as postdoc researcher Thomas Voisin examines a sample of 3D-printed stainless steel. Photo by Kate Hunts/LLNL

Stainless steel on the double

Three-dimensional printing works best with plastic and porous steel -- materials too weak for hardcore applications. But Lawrence Livermore researchers have come up with a way to 3D print tough and flexible stainless steel two times stronger than standard stainless steel. It’s an advance that could lead to faster and cheaper ways to make everything from rocket engines to parts for nuclear reactors and oil rigs.

Marine grade stainless steel is valued for its performance under corrosive environments and for its high ductility -- the ability to bend without breaking under stress -- making it a preferred choice for oil pipelines, welding, kitchen utensils, chemical equipment, medical implants, engine parts and nuclear waste storage. However, conventional techniques for strengthening this class of stainless steels typically comes at the expense of ductility.

However, the new LLNL methodology could open the floodgates to widespread 3D printing of such stainless steel components, particularly in the aerospace, automotive and oil and gas industries, where strong and tough materials are needed to tolerate extreme force in harsh environments.

Lawrence Livermore National Laboratory has joined with partners at other national labs, industry and academia in the Accelerating Therapeutics for Opportunities in Medicine (ATOM) consortium, aimed at creating a new paradigm of cancer drug discovery.

Speeding up cancer therapies

Two organizations in the San Francisco Bay Area and two outside have come together to cut the time it takes to discover cancer drugs from about six years to one.

The effort, which launched last week, brings together experts in drug discovery at the University of California at San Francisco, experts in supercomputing at Lawrence Livermore National Laboratory, experts in chemical and biological data at GlaxoSmithKline, and experts in medicine at the Frederick National Lab for Cancer Research. The project expects to reduce the time of drug discovery from the current approximately six years to just 12 months.

The consortium, called Accelerating Therapeutics for Opportunities in Medicine (ATOM), is aimed at transforming the way cancer drugs are discovered by creating an open and sharable platform that integrates high-performance computing, shared biological data from public and industry sources and emerging biotechnologies to dramatically accelerate the discovery of effective cancer therapies.

A new ground-based radar simulation can convert model data to what a cloud radar directly observes.

Seeing through the clouds

Lawrence Livermore researchers are workding to develop a ground-based radar simulator that converts model data to what a cloud radar can directly observe.

"The creation of the ground-based cloud radar simulator represents an important step that ARM (Climate Research Facility) has taken to address the gap between field data and models, and make the data-model comparison more meaningful," said principal investigator Shaocheng Xie of Lawrence Livermore.

The simulator bridges differences between climate model-simulated clouds and ARM radar observations in how they address spatial scale and properties of liquid and solid water in the atmosphere. The new tool has been incorporated into the Cloud Feedback Model Intercomparison Project Observation Simulator Package (COSP), a community satellite simulator package.

For the first time, researchers have devised a model to describe electron behavior at the quantum level.

Going to the extreme

A new source of clean energy might one day emerge from research that shows how electrons behave under the extreme temperatures and densities found within planets and stars, according to work from the United States and United Kingdom.

Until now, there have only been approximate models of electron behavior when large numbers are interacting, as is the case with "warm dense matter." Now, researchers from Lawrence Livermore National Laboratory, Imperial College Kiel University and Los Alamos National Laboratory have developed an accurate simulation in which they have much greater confidence. The new model should be possible to model planetary interiors, solids under intense laser irradiation, laser-activated catalysts and other warm dense systems.

The team has now achieved the first complete description of the thermodynamic properties of interacting electrons in an electron gas in a range of warm dense matter.

A new Lawrence Livermore project allows objects, such as helmet cushioning, to return to its original shape after impact.

4D printing creates all shapes and sizes

For the first time ever, researchers at Lawrence Livermore have 3D printed composite silicone materials that are flexible, stretchable and possess shape memory behavior. The breakthrough could lead to a new wave of innovations from body-heat-activated helmet cushioning to form-fitting shoes.

The researchers added hollow, gas-filled "micro-balloons" into silicone-based ink, letting them 3D print devices at elevated temperatures that shrink when they cool. When reheated, the gas in the micro-balloons expands, causing the structure to return to its original shape.

When combined with 3D printing, this shape memory behavior is often referred to as "4D printing," with the fourth dimension being time.