LAB REPORT

Science and Technology Making Headlines

Nov. 17, 2017

Lawrence Livermore’s Sierra supercomputer came online earlier this month.

The race toward exascale

The 50th TOP500 list of the fastest supercomputers in the world has China overtaking the U.S. in the total number of ranked systems.

While Sequoia, an IBM BlueGene/Q system installed at Lawrence Livermore National Laboratory, is the No. 6 system on the list with a mark of 17.17 petaflops, the race toward exascale isn’t quite over.

Earlier this month, Sierra, LLNL’s next supercomputer, came online. At its peak, the IBM-built Sierra is projected to provide four to six times the sustained performance and five to seven times the workload performance of Sequoia with a 125 petaFLOP/s peak. At approximately 11 megawatts, Sierra also will be about five times more power efficient than Sequoia.

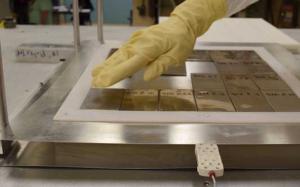

Plutonium plates are hand-stacked onto an aluminum tray during the first Lawrence Livermore-designed criticality experiment in 40 years. The "vintage plutonium" plates were produced in the 1960s, steel plated to prevent oxidation and used through the '80s to mock up nuclear reactor cores.

It’s critically important

Gathered in a control room deep in the Nevada desert, a team of researchers from Lawrence Livermore and Los Alamos national laboratories watched safety monitors as a carefully layered stack of plutonium inched toward "critical"-- the point at which fissile material can sustain a nuclear chain reaction. It took five years of planning, calculations and preparatory experiments, but they had successfully conducted the first LLNL-designed critical experiment in 40 years.

The experiment was one in a series that aims to help ensure plutonium operations continue to be conducted safely. The work is important to LLNL's mission of assessing the safety, security and effectiveness of the U.S. nuclear stockpile without testing.

There have been tens of thousands of critical configurations measured over the last 70 years, but only a small subset is considered "benchmark quality" (data that codes can be judged against) by the nuclear criticality safety community. The more exact the data that underpins the safety codes, the more confidence researchers have in their codes predicting when an assembly will go critical.

A child plays with an Einstein toy that Lawrence Livermore gave away at the annual Bay Area Science Festival in San Francisco.

Science for the masses

Lawrence Livermore was on display at the recent Bay Area Science Festival at AT&T Park in San Francisco.

The 7th annual Discovery Day at AT&T Park featured hundreds of activities to "unleash your inner scientist" and explore some of the scientific and technical work going on at the national labs, colleges and universities and research centers located throughout the Bay Area. Once again, Lawrence Livermore National Laboratory was on display with two booths on the promenade level.

Lawrence Livermore featured its popular Fun With Science interactive program, 3D virtual tours of Lab programs and special energy bikes that challenged participants' peddle power and gauge just how much wattage it takes to keep a household going.

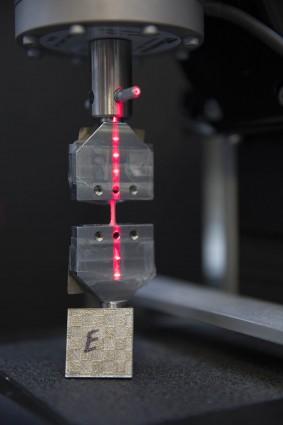

Researchers say the ability to 3D print marine-grade, low-carbon stainless steel (316L) could have widespread implications for industries such as aerospace, automotive, and oil and gas.

3D is the magic number

Scientists at Lawrence Livermore have developed a way to 3D print stainless steel that results in materials that are up to three times stronger than steels created using traditional techniques.

The team was able to 3D print real components in the lab with a low carbon stainless steel (316L), and the material’s performance was actually better than those made with the traditional approach. That’s a big jump. Tests have shown that under some conditions the material is three-times stronger than conventionally made steel.

Stainless steel is a popular material for manufacturing across many different industries. Creating a printable version of the alloy has proven difficult, however, because the final material is so porous that it is much weaker and likely to fracture.

Lawrence Livermore had developed a process that combined lasers and rapid cooling to fuse metal alloy particles densely together. A computer-driven version of that process allows them to control the material from the nanoscale to micron scale, including structures in the steel that can prevent fractures.

Lab Report takes a break

The Lab Report will take a break for the Thanksgiving holiday. It will return Dec. 1.