LAB REPORT

Science and Technology Making Headlines

Feb. 2, 2018

Jupiter is not only the largest planet in our solar system, it's also the oldest, according to new research from Lawrence Livermore National Laboratory. Image courtesy of NASA

Jupiter: one old gas ball

In our solar system, Jupiter is not only the largest planet but it’s also the oldest. It is so large, that it would take 10 Earths to make up the diameter of Jupiter.

Researchers from Lawrence Livermore and Munster University of Germany announced that Jupiter is the planet's oldest planet in the solar system.

News of Jupiter's age is known after the discovery of a meteorite that fell to Earth. The meteorite rocks were studied by measuring the tungsten isotope and the amount of molybdenum. The result is that meteorites come from two different sources that are about 2-3 million years apart. It is estimated that the separation began about one million years after the solar system began to take shape.

Hits to the head, whether on the football field or battleground, can cause chronic traumatic encephalopathy.

Going head to head

A new study by Lawrence Livermore researchers and collaborators shows that hits to the head, not concussions, cause chronic traumatic encephalopathy (CTE).

CTE is the neurodegenerative disease traced back to the kind of head trauma experienced by football players, other athletes and combat veterans.

As it turns out the concussion is irrelevant for triggering CTE; rather, it’s really the hit that counts.

The team analyzed the brains of teenagers with head injuries and used mice to recreate head trauma, revealing more about the origins of CTE and its relationship to traumatic brain injuries (TBI), concussions and subconcussive head injuries.

Lawrence Livermore researchers and collaborators have used a new material that allows smart windows to generate electricity. Credit: iStock

Windows find their place in the sun

Imagine a smart window that becomes transparent when it is dark or cool, but darkens when the sun is bright, converting that sunlight into electricity.

Typical smart windows absorb or reflect sunlight without actually converting the solar energy into a useful form. However, the new photovoltaic windows would convert the sunlight on bright days into energy that provides more functional integration with buildings, automobiles, information displays and potentially many other technologies.

Lawrence Livermore and Lawrence Berkeley scientists discovered that a form of perovskite, one of the newest materials in solar research due to its high power conversion efficiency, works surprisingly well as a reversible photoactive semiconductor material that can be switched between a transparent state and a non-transparent state, without degrading its electronic properties.

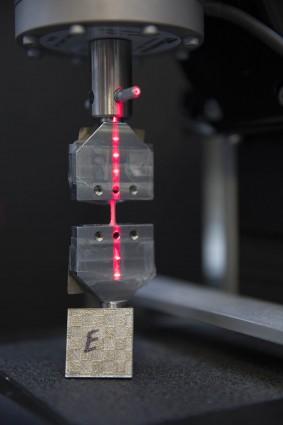

Volumetric 3D printing enables researchers to build complex 3D parts using hologram-like 3D images flashed into photosensitive resin.

Making good time

Advancements in 3D printing markedly improved design capabilities as well as shrunk manufacturing time. However, the technology has generally been limited by layer-based printing methods, which, although faster than traditional methods, can take up to several hours to complete.

Researchers at Lawrence Livermore, along with collaborators at UC Berkeley, the University of Rochester and the Massachusetts Institute of Technology (MIT), are working on a new 3D printing method to push the boundaries of this technology.

The team discovered what they call “volumetric” 3D printing, which allows them to build complex 3D parts in a fraction of the time of traditional layer-by-layer printing by using laser-generated, hologram-like 3D images flashed into photosensitive resin. It also works better in zero gravity than traditional methods, expanding the possibility of space-based production.

Researchers say the ability to 3D print marine grade, low-carbon stainless steel (316L) could have widespread implications for industries such as aerospace, automotive and oil and gas.

3D printing going strong

Lawrence Livermore researchers have achieved a breakthrough in 3D printing, by creating a marine-grade stainless steel.

According to the researchers, the low-carbon Type 316L SS alloy, valued for its corrosion resistance and high ductility, is a popular choice for products that include oil pipelines, welding metals, kitchen utensils, chemical equipment, medical implants, engine parts and nuclear waste storage systems.

One usual drawback of coarse-grained Type 316L stainless steel is its low yield strength, the researchers note, adding that many traditional metallurgical routes to strengthening the material, such as cold rolling or forging, often come at the expense of tensile ductility. However, they believe a new discovery could soon change that equation -- and it may extend to other lighter-weight alloys as well.

The team was able to 3D print real components in the lab with 316L stainless steel, and the material’s performance was actually better than those made with the traditional approach. “That’s really a big jump. It makes additive manufacturing very attractive and fills a major gap,” according to LLNL scientist Morris Wang.