LAB REPORT

Science and Technology Making Headlines

May 11, 2018

Lawrence Livermore’s National Ignition Facility houses the largest and most energetic laser in the world.

Three is the magic number

When it comes to huge machines that could change the world, Lawrence Livermore’s National Ignition Facility fits the bill.

Coming in at No. 3, the three football fields-sized NIF structure, holds the largest, most energetic and most precise laser in the world.

Its lasers are used to create conditions like those within the cores of stars and giant planets, which helps scientists gain an understanding about these areas of the universe. NIF also is trying to achieve fusion ignition, the same reaction that powers the sun.

GE and Lawrence Livermore are developing metal 3D-printed parts to repair U.S. Navy ships.

Getting into shipshape

GE Global Research and Lawrence Livermore are creating 1:1 scale twin digital models of metal 3D-printed parts for the U.S. Navy.

According to recent estimates, the Navy will depend upon approximately 1,000 3D-printed parts by the end of 2018. Through the digital twin project, this number could rise significantly between now and the year 2021/2022 as the program will be designed to expedite the 3D-printed part qualification and certification process.

The program will specifically be used to maintain in-service ships, aircraft and vehicles.

LLNL will provide its “feed-forward” design methods to ensure fail-safe accuracy of first-time 3D-printed parts through the Accelerated Certification of Additively Manufactured Metals (ACAMM) project.

There are many asteroids that could hit Earth. Lawrence Livermore researchers are working a project to deflect them

HAMMER time

Space is filled with many asteroids that could lead to disastrous consequences if they ever reach all the way do Earth.

LLNL scientists are helping humans by working as part of a national planetary defense team, and so far, they have managed to design a conceptual spacecraft that’s meant to deflect any and all Earth-bound asteroids.

After finishing the work on their initial design, they evaluated it to understand how it could work against a massive asteroid. The researchers came up with a spacecraft that measures 9 meters tall and weighs a total of 8.8 tons. They’ve called it the HAMMER vehicle, where HAMMER stands for Hypervelocity Asteroid Mitigation Mission for Emergency Response. It features a modular-design that would essentially allow it to be used as either a kinetic impactor -- kind of like a battering ram -- or a dedicated transport vehicle for a specialized nuclear device.

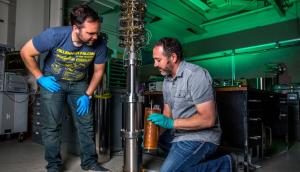

Lawrence Livermore postdoc Nathan Woollett and LLNL staff scientist and ADMX co-spokesman Gianpaolo Carosi work on the cryostat system in which LLNL places its test microwave cavity. Photo by George Kitrinos/LLNL

Can you hear me now?

Forty years ago, scientists theorized a new kind of low-mass particle that could solve one of the enduring mysteries of nature: What is dark matter made of? Now a new chapter in the search for that particle, the axion, has begun.

The Axion Dark Matter Experiment has unveiled a new resul, that places it in a category of one: It is the world’s first and only experiment to have achieved the necessary sensitivity to “hear” the telltale signs of these theoretical particles. This technological breakthrough is the result of more than 30 years of research and development, with the latest piece of the puzzle coming in the form of a quantum-enabled device that allows ADMX to listen for axions more closely than any experiment ever built.

“The initial versions of this experiment, with transistor-based amplifiers, would have taken hundreds of years to scan the most likely range of axion masses. With the new superconducting detectors, we can search the same range on timescales of only a few years,” says Gianpaolo Carosi, co-spokesperson for ADMX and scientist at Lawrence Livermore National Laboratory.

The Illinois Industrial Carbon Capture and Storage (ICCS) project safely and permanently stores more than 1 million tons of carbon dioxide a year. The project captures CO2 from Archer Daniel Midland’s Decatur corn processing facility and stores it almost a mile and a half underground. ICCS is designed to demonstrate carbon capture and storage technology in a saline reservoir at commercial-scale. Image courtesy of Archer Daniel Midland.

Rounding up carbon for a profit

To better understand the near-term commercial potential for capturing and storing atmospheric carbon dioxide (CO2), researchers from Lawrence Livermore have mapped out how CO2 might be captured from existing U.S. ethanol biorefineries and permanently stored (or sequestered) underground.

There are more than 200 existing U.S. biorefineries that emit 45 million metric tons (MT) of CO2 annually from fermentation. Looking only at the cost of capturing the CO2 -- not including building pipelines or sequestering the captured CO2 -- the team found that 60 percent of current CO2 emissions (i.e., 27 MT per year) could be captured for less than $25 per metric ton.

“Proposed modifications to the California Low Carbon Fuel Standard and recent revisions to existing federal tax credits create a substantial near-term opportunity to permanently sequester biogenic CO2,” said LLNL scientist Sean McCoy. “This financial opportunity could not only spur the growth of carbon capture and sequestration, but also reduce the lifecycle impacts of biofuels we use today, help fulfill mandates for low-carbon fuels in the U.S. and elsewhere and support development of new carbon-negative fuels.”