LAB REPORT

Science and Technology Making Headlines

June 22, 2018

This rendering of NIF’s target chamber shows the target positioner moving into place. Pulses from high-powered lasers race through the facility at the speed of light and arrive at the center of the chamber within a few trillionths of a second of each other, aligned to the accuracy of the diameter of a human hair.

Another step closer

Lawrence Livermore researchers at the National Ignition Facility have taken another step toward their goal of using lasers to attain a self-sustaining nuclear fusion reaction. The team conducted experiments that doubled previous records both for neutron yield (now at 1.9 x 1016) and fusion energy output (now at 54 kilojoules) generated from capsules containing cryogenic deuterium-tritium fusion fuel.

The progress was due largely to changes to both the capsules and the hohlraums -- cylinders in which the capsules are suspended -- that helped maintain the symmetry of the fuel’s implosion.

This is a critical step forward in the quest for achieving laboratory ignition. Ignition -- the point at which the heating provided by nuclei in the plasma exceeds the heat lost from the system -- has been pursued primarily for its relevance to nuclear weapons physics, since it would mimic on a laboratory scale the dynamics in a weapon’s fusion stages. Laser fusion also is considered a possible future energy source.

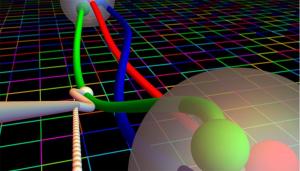

A simulation of the topological atoms in a C2H4 molecule as defined by the quantum theory of atoms in molecules and computed using TopoMS, with each color representing an atom.

Atoms are crystal clear

Using machine learning, evolutionary algorithms and other advanced computational techniques, researchers at Lawrence Livermore have successfully modeled how atoms are arranged between the crystals that make up most materials, a development that could impact how future materials are designed and optimized.

While most materials might appear to the naked eye as uniform solids, they're actually composed of tiny crystallites or grains separated on the atomic level by interfaces that scientists call grain boundaries. Because of their importance to material properties and functions, the structures of these grain boundaries have been extensively investigated. However, searching through the billions of possible structures by hand and trying to predict their behavior has been an exercise in futility.

Researchers at LLNL, the University of Nevada-Las Vegas, Stony Brook University and UC Davis have devised a method based on evolutionary algorithms and machine learning capable of combing through the vast space of how atoms in grain boundaries can be arranged and predicting how they will interact under certain conditions. Scientists said the method finally provides a way to predict material properties and could lead to major breakthroughs in developing materials with greater strength, more heat resistance or higher conductivity.

A new study shows that the East Antarctica Ice Sheet did not recede much during a time period when carbon dioxide levels were very similar to the levels today.

No sign of receding ice line

Large parts of the massive ice sheet of East Antarctica did not recede significantly during a time when atmospheric concentrations of carbon dioxide were similar to current levels, according to a team of researchers including those from Lawrence Livermore. The finding could have significant implications for the global increase in sea level.

The East Antarctic ice sheet is one of the three most important ice sheets observed closely by scientists as global temperatures and carbon dioxide levels rise, glaciers melt and sea levels rise. Of the three, the East Antarctic Ice Sheet is the largest potential contributor to sea level rise.

This study focused on the portion of the ice sheet that lies above the ocean. It contains enough water to cause up to 34 meters of sea level rise if the ice sheet melts completely.

To measure the stability of the ice sheet, the researchers took ultrasensitive analytical measurements of chemical signatures in sediment samples taken from the seabed. They came to the conclusion that some ice in the southernmost part of the continent could be stable in a warm climate, as was the case during the Pliocene Epoch.

Beta decay, the decay of a neutron to a proton with the emission of an electron and an electron-anti-neutrino. In the figure gA is depicted as the white node on the red line. The square grid indicates the lattice. Image by Evan Berkowitz/Forschungszentrum Jülich/Institut für Kernphysik /Institute for Advanced Simulation

Life and death of a neutron key to universe

Using some of the world's most powerful supercomputers, an international team including scientists from Lawrence Livermore released the highest-precision calculation of a fundamental property of protons and neutrons known as nucleon axial coupling.

This quantity determines the strength of the interaction that triggers neutrons to decay into protons -- and can be used to more accurately predict how long neutrons are expected to "live."

The fact that neutrons decay into protons is an important fact in the universe. It tells how atomic nuclei -- made of protons and neutrons -- were created after the Big Bang. Neutron lifetime also has bearing on the relative abundance of atoms like hydrogen and helium in the universe today, and how that balance will affect the formation of future stars.

The new calculation could also help scientists determine which of two approaches to experimentally measure neutron lifetime is more accurate -- and whether the several-second discrepancy between the two could potentially point to the existence of yet-to-be discovered particles.

LLNL researchers (from left) Phil Depond, Nick Calta, Aiden Martin and Jenny Wang are part of a multi-lab team that has successfully designed, built and tested a portable diagnostic machine capable of probing inside metal parts as they’re being 3D printed. Photo by Julie Russell/LLNL

3-D printing defects from flaws

Metal 3D printing has enormous potential to revolutionize manufacturing, but many industries have been slow to adopt the technology due to concerns over part quality and certification, which is essential to building confidence in the critical parts used in automotive and aerospace applications.

Through carefully designed experiments that replicate the manufacturing process, researchers at Lawrence Livermore have previously unveiled many of the complex mechanisms that can drive defect formation and limit part quality in metal 3D printing.

More recently, LLNL researchers have teamed up with scientists at the SLAC National Accelerator Laboratory and Ames Laboratory to better understand this process, examine more directly what exactly leads to defects in printed parts and how those flaws might be avoided.

One of the first scientific papers to come out of the partnership examines the use of X-ray imaging and diffraction to peer into metal parts as they’re being printed during the laser powder-bed fusion process, a common metal 3D printing approach. Building on years of Lab research into the physics behind the process, LLNL researcher Nick Calta and his team have designed and built a portable diagnostic machine capable of probing the melt pool, the area where the passing laser meets the metal powder, fusing and producing the layers that eventually become a fully formed part.