LAB REPORT

Science and Technology Making Headlines

Sept. 7, 2018

LLNL researchers created inks made of gold and silver microparticles. After printing, the 3D parts were heated to allow the particles to coalesce into a gold-silver alloy. The parts were put into a chemical bath that removed the silver to form porous gold within each beam or filament. Image by Ryan Chen/LLNL

Going for the gold

Nanoporous metals are superior catalysts for chemical reactions due to their large surface area and high electrical conductivity, making them perfect candidates for applications such as electrochemical reactors, sensors and actuators.

Lawrence Livermore researchers, along with their counterparts at Harvard University, report on the hierarchical 3D printing of nanoporous gold, a proof of concept that researchers say could revolutionize the design of chemical reactors.

“If you consider traditional machining processes, it’s time consuming and you waste a lot of materials -- also, you don’t have the capability to create complex structures,” said LLNL postdoctoral researcher Zhen Qi. “By using 3D printing we can realize macroporous structures with application-specific flow patterns. By creating hierarchical structures, we provide pathways for fast mass transport to take full advantage of the large surface area of nanoporous materials. It’s also a way to save materials, especially precious metals.”

New research shows that the compression of a black hole may be able to reignite a dead star such as the white dwarf above. Image courtesy of NASA.

Resuscitating a dead star

A white dwarf, the dead core of a star like our sun, can get caught in the gravitational grip of a black hole. If it passes close enough, inside the so-called tidal radius, the black hole’s gravity will rip the dead star apart in a cataclysmic tidal disruption event, or TDE, as it is simultaneously stretched and compressed in opposite directions.

New research by Lawrence Livermore and colleagues from the University of Charleston shows the compression may be powerful enough to briefly reignite nuclear fusion in the white dwarf, bringing the star back to life, in effect, for a few seconds before it is torn apart.

While some of the debris will merge with the black hole, computer simulations show a “significant fraction” will be ejected back into space, providing raw material, including newly formed heavy elements, for future stellar generations.

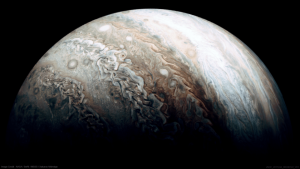

Jupiter’s history includes a period of growing pains as kilometer-sized molecules smashed into the giant planet, which forced the planet to grow more slowly. Image courtesy of NASA.

Jupiter’s growth spurt

New research suggests why Jupiter, the largest planet in the solar system, waited about 2 million years for its early formation growth spurt.

A team led by a Swiss researcher found that kilometer-size worlds smashed into the giant planet during that time, generating zones of high energy. This bombardment made it difficult for gas molecules to accrete, forcing the planet to grow more slowly.

The solar system is about 4.5 billion years old, and a popular formation theory for planets says that they were formed out of an orbiting cloud of gas and dust that surrounded the young sun. Over time, the gas and dust clumped into small worlds, gradually accreting to each other to form the planets.

The new data lined up with a separate set of results that another team of researchers -- led by Thomas Kruijer, a researcher at Lawrence Livermore National Laboratory -- gleaned from observations of meteorite compositions.

A sample of microarchitectured graphene aerogel, made from one of the lightest materials on Earth, sits atop a flower.

Graphene in all shapes and sizes

LLNL researchers and collaborators from Virginia Tech have developed a novel way to 3D print complex objects of one of the highest-performing materials used in the battery and aerospace industries.

Previously, researchers could only print this material, known as graphene, in 2D sheets or basic structures. But project engineers 3D printed graphene objects at a resolution and order of magnitude greater than ever before printed, which unlocks the ability to theoretically create any size or shape of graphene.

Because of its strength - graphene is one of the strongest materials ever tested on Earth - and its high thermal and electricity conductivity, 3D-printed graphene objects would be highly coveted in certain industries, including batteries, aerospace, separation, heat management, sensors and catalysis.

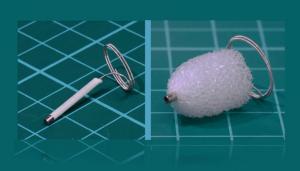

The Food and Drug Administration approved the use of IMPEDE, a medical device used to treat bleeding abnormalities by deliberately blocking blood flow, which incorporates expanding shape memory polymer technology partly developed at Lawrence Livermore National Laboratory. Image by Todd Landsman/Shape Memory Medical.

New device commits to memory

The Shape Memory Medical IMPEDE embolization plug is based on shape memory polymer (SMP) foams, porous polymeric materials capable of changing from one shape to a second "memorized" shape upon a change of environment. The ultra-low density SMP polyurethane formulation and pore sizes can be modified, creating materials with a wide range of different properties. Once SMP foam has been formed into its primary expanded shape, it can be crimped to a convenient secondary shape.

The Food and Drug Administration has approved the use of the medical device in humans for deliberately blocking blood flow to treat bleeding abnormalities or other conditions, a procedure known as embolization. The device integrates expanding shape memory polymer technology that was partly developed at Lawrence Livermore.

Shape Memory Medical was founded by former LLNL scientist Duncan Maitland. The device can be “programmed” into a particular shape, made thin enough to fit in a catheter and expand to its former shape when exposed to stress or heat. The advantages of IMPEDE, Maitland said, include simple delivery through any diagnostic catheter, ease of navigation through twisted blood vessels and quick, stable embolization without compromising the vessel wall.