LAB REPORT

Science and Technology Making Headlines

March 15, 2019

LLNL and UC Berkeley researchers used a new 3D-printing technique to create a 40-mm-tall version of Auguste Rodin’s The Thinker. Photo by Stephen McNally/UC Berkeley.

Lighting the way

Lawrence Livermore researchers are using a new 3D printer that uses light to shape objects that are smoother, more flexible and more complex than those produced with conventional 3D printers.

Several schemes now exist to assemble, or “print,” 3D objects through repeated 1D or 2D operations. But such point-by-point or layer-by-layer approaches often create ragged-edged figures, constrain their shapes and can take hours.

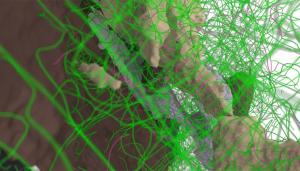

But a group of researchers from Lawrence Livermore and the University of California, Berkeley, have developed a 3D printing technique that circumvents those limitations. The method, called computed axial lithography, selectively solidifies parts of a photosensitive liquid polymer by exposing it to a dynamically evolving light field.

In practice, the researchers project a series of computed 2D images from multiple angles onto a rotating cylinder of the liquid. The superposition of exposures produces an energy dose sufficient to solidify the material into the desired shape -- for example, a 40-mm-tall version of Auguste Rodin’s The Thinker — in a matter of minutes.

Under a newly awarded HPC4Manufacturing project, LLNL will work with U.S. Steel Corporation on a hot strip-mill simulation model that will provide predictions of through-thickness temperature, deformation behavior and associated microstructure. Photo courtesy of U.S. Steel Corporation.

Heavy metal gets its day

The High Performance Computing for Manufacturing Program (HPC4Mfg) has doled out $1.2 million in federal funding for four public/private projects aimed at solving key manufacturing challenges in steelmaking and aluminum production through supercomputing.

The most HPC4Mfg solicitation focused on applying the unparalleled high-performance computing capabilities of the Department of Energy’s national laboratories to steelmaking and aluminum production processes. Under the program, each selected industry partner will have access to the national labs’ HPC machines and expertise to help these industries become more competitive, boost productivity and support American manufacturing jobs.

“Primary metals industries are significant energy users, so opportunities to reduce energy consumption in this area is of great interest to our sponsors,” said HPC4Mfg Director Robin Miles of Lawrence Livermore National Laboratory (LLNL). “Additionally, this program is helping U.S. steelmakers produce the higher-strength steels vital to lightweighting the next generation of automobiles.”

Funded by DOE’s Advanced Manufacturing Office, the HPC4Mfg Program is administered by LLNL along with managing principal laboratories Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory.

Microcapsules containing sodium carbonate solution are suspended on mesh during carbon dioxide absorption testing. The mesh allows many capsules to be tested at one time while keeping them separated, exposing more of their surface area.

Microcapsules to the rescue

Use of fossil fuels to generate energy releases a tremendous amount of carbon dioxide into the atmosphere.

A team of Lawrence Livermore and University of Pittsburgh researchers have found a safer and more efficient way to capture that carbon dioxide at the source: reusable microcapsules that reduce the cost of post-combustion carbon capture processes.

The new approach is very different than the conventional method of capturing carbon dioxide at a power plant. In the new process, the team put the solvent into tiny microcapsules instead of flowing a chemical solvent down a tower. The proposed design of a carbon capture reactor includes several microcapsules that are placed into a container. The power plant exhaust gas flows through the microcapsules.

Conventional reactors require high temperature, which in turn increases plant operating costs. According to the researchers, the new design will be a smaller structure and will consume less electricity to operate, thereby reducing costs.

Using flexible multielectrode arrays designed and developed at LLNL, a team of researchers at UCSF led by professor Loren Frank (center), was able to continuously measure the neural activity of nearly 400 single neurons over a period of at least five months from multiple regions of rodent brains. Photo: Noah Berger/UCSF

Wrapping a head around the brain

Scientists could soon have a long-term, real-time window into how the brain communicates within itself.

Biomedical engineers at Lawrence Livermore National Laboratory teamed with researchers from the University of California, San Francisco to build a sensor network that records brain activity. It uses high-density implantable sensors to collect real-time data over relatively long periods of time and across several areas of the brain.

The network can continuously measure activity in nearly 400 single neurons over a period of at least five months from devices distributed in several regions of rodent brains. Using an automated spike sorter developed at UCSF, the researchers concluded the recordings are stable enough to track large numbers of individual neurons for more than a week. The research sprung from a project aimed at better understanding the mechanisms of learning that occur over time.

“Being able to record from several regions for long periods of time with high fidelity lets you look at patterns of learning and how memory changes over time,” LLNL researcher Angela Tooker said. “Now we can see what is changing from day to day in response to training, retraining and new stimuli. It opens up a whole new field.”

Mono cropping and routine tillage leads to massive erosion of topsoil.

Carbon capture hits the dirt

From increased wildfire damage and the threats from rising sea levels, to ocean acidification and the impacts on human migration patterns, the effects of global warming are already being felt. To avoid the planet from warming 1.5°C above pre-industrial figures, global carbon emissions need to decrease.

Much of the conversation surrounding what to do turns skyward — reduced emissions from power plants, for example. Many companies also are vying to produce the first to-scale, commercially viable negative emissions technology — one that sucks and stores away more CO2 than it uses.

But a growing number of experts say we need to look downward, arguing that the carbon sequestering capacity of the soil under our feet has the potential to help tackle and reverse, perhaps significantly, human-caused global warming.

In the U.S., industrial farming practices like monocropping and routine tillage have led to the massive erosion of topsoil, where most of the carbon is stored. “Those practices are things that can be easily avoided,” said Roger Aines, chief scientist of the energy program at Lawrence Livermore National Laboratory. “When we’re dealing with sensitive soils, like in these wetlands and peat soils, you shouldn’t plow them or dig them up. When you’re dealing with soils that could blow away, you should keep a cover crop.”