LAB REPORT

Science and Technology Making Headlines

Nov. 8, 2019

LLNL physicist Tammy Ma (right) talks to CBS Mission Impossible host Miranda Cosgrove about the National Ignition Faclity.

Mission Unstoppable

Laser plasma physicist Tammy Ma of Lawrence Livermore knows a lot about fusion – creating a star on Earth that could supply a clean, limitless source of energy. Using the National Ignition Facility, the world’s largest and most energetic laser and a key component of the effort to keep the nuclear deterrent safe and secure, Ma and her LLNL colleagues are on their way to doing just that.

LLNL chemist Dawn Shaughnessy is part of a team that discovered five new elements on the periodic table, one of them being named after the lab she works at, Livermorium (element 116). Shaughnessy’s interest in chemistry started as a child in elementary school when she received a chemistry kit. Her interest grew from there and she went on to learn about radiochemistry in graduate school. It was there where she found that creating something new by combining two substances would be the coolest job in the world.

Ma and Shaughnessy were recently featured on CBS Saturday Morning show “Mission Unstoppable.”

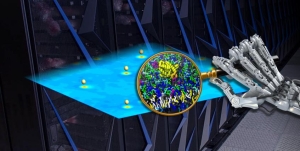

Lawrence Livermore National Laboratory researchers, along with scientists from Los Alamos National Laboratory, the National Cancer Institute and other institutions, are using machine learning as a virtual magnifying glass to study interesting regions of RAS protein/lipid simulations in higher detail. Image by Tim Carpenter/LLNL

A model for cancer research

Computational scientists, biophysicists and statisticians from Lawrence Livermore and Los Alamos national laboratories are leading a massive multi-institutional collaboration that has developed a machine learning-based simulation for next-generation supercomputers capable of modeling protein interactions and mutations that play a role in many forms of cancers.

The research stems from a pilot project in the Joint Design of Advanced Computing Solutions for Cancer program, a collaboration between the Department of Energy's Office of Science, the National Nuclear Security Administration and National Cancer Institute that is supported in part by the Cancer Moonshot. The work is being published by the 2019 Supercomputing Conference, held Nov. 17-22 in Denver, where it is among the finalists for the conference's Best Paper award.

The paper, which also includes contributions from Oak Ridge National Laboratory, the Frederick National Laboratory for Cancer Research and IBM, describes a predictive and multi-scale approach to model the dynamics of RAS proteins -- a family of proteins whose mutations are linked to more than 30 percent of all human cancers -- and lipid membranes, as well as the activation of oncogenic signaling through interaction with RAF proteins. NCI established the RAS Initiative in 2013 to explore the biology of mutant (oncogenic) RAS and to ultimately create new therapeutic opportunities for RAS-related cancers.

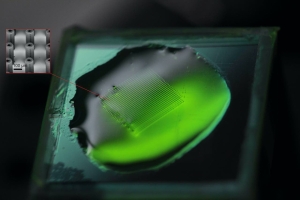

A printed micropillar forest submerged in the photopolymer resist prior to development. The forest contains 900 micropillars over a 7 × 7 milimeter area and was printed in less than 90 minutes as compared to more than a day of printing with serial techniques. Image courtesy of Vu Nguyen and Sourabh Saha/Georgia Tech University.

Tiny structures in a snap

Using a new time-based method to control light from a laser, researchers from Lawrence Livermore have developed a nanoscale 3D printing technique designed to fabricate tiny structures a thousand times faster than conventional two-photon lithography (TPL) techniques without sacrificing resolution.

Despite the high throughput, the new parallelized technique — known as femtosecond projection TPL (FP-TPL) — produces depth resolution of 175 nanometers, which is better than established methods and can fabricate structures with 90-degree overhangs that, currently, cannot be made. The technique could lead to manufacturing-scale production of bioscaffolds, flexible electronics, electrochemical interfaces, micro-optics, mechanical and optical metamaterials and other functional micro- and nanostructures.

Existing nanoscale additive manufacturing techniques use a single spot of high-intensity light — typically around 700 to 800 nanometers in diameter — to convert photopolymer materials from liquids to solids. Because the point must scan through the entire structure being fabricated, the existing TPL technique can require many hours to produce complex 3D structures, which limits its ability to be scaled up for practical applications.

“The parallel two-photon system that has been developed is a breakthrough in nanoscale printing that will enable the remarkable performance in materials and structures at this size scale to be realized in usable components,” said LLNL’s Center for Engineered Materials and Manufacturing Director Chris Spadaccini.

DOE-ling out cash for energy efficiency

The Department of Energy (DOE) announced this week up to $4 million for new projects to support manufacturers in improving energy efficiency, increasing productivity, and accelerating manufacturing innovation.

The High Performance Computing for Energy Innovation (HPC4EI) Initiative, managed by DOE’s Office of Energy Efficiency and Renewable Energy (EERE), is seeking qualified industry partners to work collaboratively with DOE’s National Laboratories on projects that use high performance computing (HPC) to solve key technical challenges in the areas of manufacturing and mobility.

HPC4EI, the umbrella initiative for HPC for Manufacturing, HPC for Materials and HPC for Mobility, is made up of nine labs led by Lawrence Livermore National Laboratory. The labs partner with the private sector to utilize DOE’s supercomputing capabilities and advanced simulation and data analytics techniques to improve manufacturing processes and develop better products.

LLNL and UC Davis researchers have developed a breath test for opioids that will be able to collect a sample in a minute rather than the 10-minute tests used today.

Take a breath

Engineers and physicians at Lawrence Livermore and the University of California, Davis (UCD), have developed a breath test for opioids that they foresee first responders using one day with overdose victims and physicians using in offices to counsel patients on prescription drug use.

The researchers have been working for about 15 years to find the best method to analyze human breath, and they now have achieved it. The research team published a paper on their findings in the Journal of Breath Research.

“We’ve developed a sampler that is appropriate in the best way to collect the exhaled breath to detect the opioids, which are present at really small concentrations inside the breath,” said UCD’s Cristina Davis. “We right now sample for about 10 minutes and then we store that sample in the freezer until we can analyze it, and we use a technology called a mass spectrometer to analyze the opioids or any drugs that we see.”

But the large mass spectrometer won’t be needed once the research team has finished their work. And, rather than the 10-minute sampling interval, their device will be able to collect a sample in a minute by the time it goes to market. Researchers envision a device as small as the Breathalyzers that law enforcement use in the field — and perhaps even less expensive than those devices.