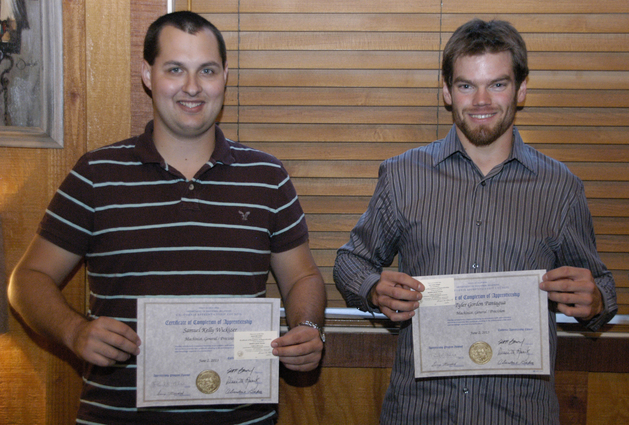

Lab machinists graduate from the Machinists Apprentice Program

Their hard work was honored late last month when they graduated from the LLNL Engineering Directorate 's Machinist Apprentice Program. It's a four year program that teaches young machinists the technical skills and safety training they need to be certified machinists at LLNL and in the State of California. Both men received their machinist certificates at a commencement ceremony at Cattlemen's Restaurant in Livermore that was attended by family, friends, colleagues and VIPS from engineering and its machinist operations. A representative from the state also was there.

"I feel a great sense of accomplishment and pride about graduating from this program as it's one of the few remaining state-recognized machinist apprentice programs," Paniagua said. "The Engineering Machinist Apprentice Program is a much sought after program in the machine tool trade."

Wickizer said the machinist apprentice program was a great experience.

"Working alongside highly talented journeyman machinists here at the Lab, I learned a wealth of new skills and continue to learn something new every day," he said. "I take pride in creating interesting and complex parts, knowing that the work done here benefits and advances the nation in science and technology. I look forward to an exciting career as a journeyman machinist."

Mike Prokosch, director of the program, said he was extremely proud of his young proteges.

"Tyler and Sam are examples of two talented young men who have dedicated themselves to becoming the best machinists they can be," said Prokosch, who began his LLNL career as an apprentice in the same program. "They should be as proud of their accomplishments as we are of them. I am confident they will have long and successful careers at the Lab."

The machinist program has a long and storied history dating back to the late 1950s. Since that time, it has produced both conventionally manufactured research products and additive manufactured products. The ultra-selective program (most applicants are turned away) provides education and training in the machine tool trade, specific to the highly specialized work done by LLNL researchers. That means machinists are manufacturing products not built anywhere else in the world.

The in-house training provides apprentices with knowledge and skills passed down by veteran machinists and from LLNL machine shop techniques refined from five decades of practice.

The program traditionally takes four years. However, Paniagua and Wickizer were able to complete it in 3.5 years. During their first year, they spent time in different sections of the machine shops to learn a variety of machines and tools used by many programs throughout the Lab. They learned shop practices to build a strong manual machining foundation in preparation for journeyman level work.

Their second year was spent mostly at a facility that's referred to as "The Main Bay" of the machine shop. They were allowed to operate larger manual lathes, mills, specialized machines for various grinding operations, horizontal boring and milling machines, as well as Computer Numerically Controlled mills.

They then moved next door to another machine shop complex, which houses both the Precision Shop and Special Materials and Manufacturing Facility (SMMF), also known as the Numerically Controlled shop. They spent the remaining two years of their apprenticeship in each of these shops to further hone the skills learned over the previous two years, while being exposed to increasingly complex job orders.

"After graduation, I will continue to work in the SMMF shop until further notice and look forward to a lengthy and exciting career here at LLNL," Paniagua said.

Contact

Kenneth K Ma[email protected]

925-423-7602

Related Links

Engineering at LLNLManufacturing at LLNL

Tags

EngineeringFeatured Articles