Lab loans state-of-the-art 3D printer to Cal Poly

(Download Image)

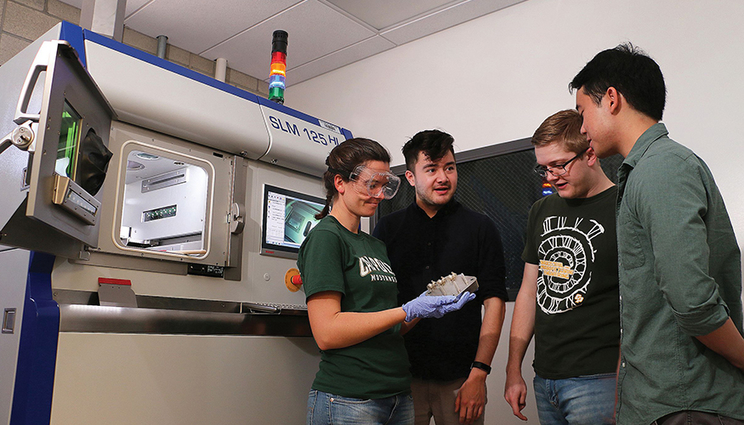

Standing next to the new SLM printer at Cal Poly San Luis Obispo are (from left) future Lawrence Livermore National Laboratory summer intern Moira Foster, and fellow students Dominique Porcincula, Ben Murray and David Otsu (who is sponsored by the Laboratory for his senior project and master thesis). Photo credit: Dennis Steers/Cal Poly San Luis Obispo College of Engineering

(Download Image)

Standing next to the new SLM printer at Cal Poly San Luis Obispo are (from left) future Lawrence Livermore National Laboratory summer intern Moira Foster, and fellow students Dominique Porcincula, Ben Murray and David Otsu (who is sponsored by the Laboratory for his senior project and master thesis). Photo credit: Dennis Steers/Cal Poly San Luis Obispo College of Engineering

California Polytechnic State University (Cal Poly) San Luis Obispo engineering students now have access to the state-of-the-art in metal additive manufacturing and the ability to perform contracted work for Lawrence Livermore National Laboratory (LLNL), thanks to a new Selective Laser Melting (SLM) machine on loan to the university.

LLNL purchased the SLM machine and is loaning it to Cal Poly’s engineering department, which includes students who have been or will be summer interns at the Lab. Besides being used to conduct research for Lab projects, LLNL hopes to enhance the existing workforce pipeline with the university, the alma mater of many current engineering employees. The school held a celebratory event including the university president and dean of engineering, as well as sponsors and representatives from LLNL, on June 2.

"The printer has put us on the map at Cal Poly," said Matt Wraith, an LLNL engineering group leader and expert in metal additive manufacturing. "The students and faculty are very interested in it. The machine’s primary focus is interacting with students and identifying students that we can hire. From our end, while the build volume is less, the laser is the same, so the product should be the same as what we can build."

Few colleges, especially Cal State schools, have metal 3D printers, Wraith explained, so the printer could benefit Cal Poly in more ways than one.

"It’s a huge deal," Wraith said. "For them to get a piece of equipment like this is a feather in their cap to recruit students."

The printer came online in March and students have been using it to work on their senior projects and theses, some in parallel with their work as LLNL interns. The machine also was recently featured on the cover of a campus engineering publication, which has generated calls from parents wanting to have their children enroll at Cal Poly specifically to work with it, according to Cal Poly engineering professor Xuan Wang.

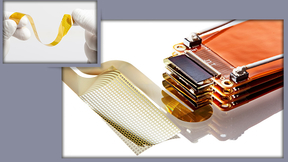

Wang, who began teaching a new additive manufacturing class in January, said the SLM printer is unique in that students can design a part, import it directly into the machine and build parts with shapes and geometries much better than traditional manufacturing. He said several of his graduate students have been hired at LLNL and companies like Boeing and Raytheon, and that he believes having the capability will give his students a competitive advantage.

"We have quite a few students who are looking at jobs and those companies are specifically looking for experience with metal 3D printing and this type of technology," Wang said. "We have a high-quality pipeline with the level of students we have here and this machine is a huge help for us. Some students came here specifically asking to do projects with LLNL and metal 3D printing, and many companies in aerospace and defense are looking for these types of skills."

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Cal Poly San Luis Obispo"Cal Poly to Celebrate Partnership with Lawrence Livermore National Laboratory"

Engineering at LLNL

Metal additive manufacturing

Tags

EngineeringFeatured Articles