Harnessing better fuel production from biomass

(Download Image)

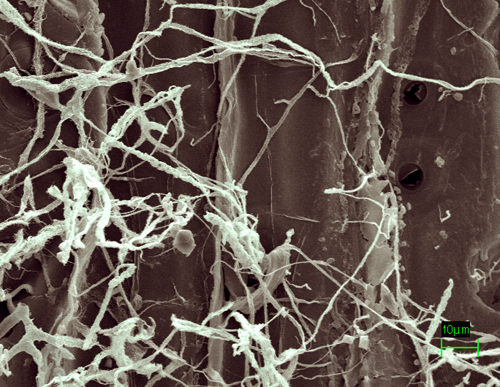

Tom Kuster/FPL Postia placenta efficiently colonizes and decays wood.

(Download Image)

Tom Kuster/FPL Postia placenta efficiently colonizes and decays wood.

An international team led by scientists from the Joint Genome Institute (JGI) and the U.S. Department of Agriculture Forest Service, Forest Products Laboratory (FPL) have translated the genetic code that explains the complex biochemical machinery making brown-rot fungi uniquely destructive to wood.

The same processes that provide easier access to the energy-rich sugar molecules bound up in the plant’s tenacious architecture are leading to innovations for the biofuels industry. The research, conducted by more than 50 authors, is reported in the Feb. 4 online edition of the Proceedings of the National Academy of Sciences (PNAS).

Among the challenges to more cost-effective production of biofuels from cellulosic biomass — the fibrous material of whole plants — is to find effective means to work around the polymer lignin, the scaffolding that endows the plant’s architecture with rigidity and protection from pests. By doing so, the organic compound cellulose — the long chain of glucose (sugar) units — can be unbound, broken down, fermented and distilled into liquid transportation fuel.

This is where the destructive capabilities of rot come in.

"The microbial world represents a little explored yet bountiful resource for enzymes that can play a central role in the deconstruction of plant biomass — an early step in biofuel production," said Eddy Rubin, director of JGI, where the genome sequencing was conducted. "The brown-rot Postia placenta’s genome offers us a detailed inventory of the biomass-degrading enzymes that this and other fungi possess."

Rubin pointed to a complementary strategy that DOE and its Bioenergy Research Centers are pursuing of targeting a new generation of plants — perennial grasses and fast-growing trees such as poplar — bred specifically as biomass for biofuels. Among the desirable characteristics of biofuel "feedstocks" is the ease by which they can be deconstructed.

Traditionally, harsh chemicals and expensive high-heat treatments have been employed. In parallel with the development of improved feedstocks is finding just the right mix of enzymes to get the most out of converting biomass into fuel.

To see the complete article or for additional information about JGI, check the Web.