Forum showcases Lab's additive manufacturing capabilities

(Download Image)

(Download Image)

Lawrence Livermore National Laboratory's cutting-edge technologies in the additive manufacturing industry were a focal point at a recent forum, which drew a crowd of more than 80 people from throughout the Bay Area. Photo by Scott Wilson/LLNL

Lawrence Livermore National Laboratory's additive manufacturing capabilities including hardware expertise, materials science R&D and high-performance computing were highlighted at a recent Silicon Valley forum.

Held at theHigh Performance Computing Innovation CenterLivermore Valley Open Campus, the event drew a standing room only crowd of more than 80 people from throughout the Bay Area. It was hosted by Silicon Valley Forum, a groupdevoted to creating connections and providing education to the Silicon Valley ecosystem of innovators, entrepreneurs and business professionals participating in emerging technologies.

The event, designed to discuss cutting-edge technologies and R&D directions emerging in the additive manufacturing (AM) industry, included a panel discussion and product exhibition from Bay Area AM companies.

"Because of the work we [LLNL] do for the government and our sponsors, we really need a stake on how things are built, and that is what has led us into additive manufacturing," said Patrick Dempsey, the Lab's manager of strategic engagements.

Dempsey has been working with California manufacturing groups to establish a network for manufacturing innovation that would leverage technologies being developed at the national laboratories to help improve American competitiveness in industry.

Taking commercial technologies to the next level

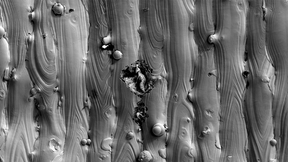

Chris Spadaccini, an LLNL engineer who leads the Center for Engineered Materials, Manufacturing and Optimization, said the Lab's AM work focuses on three areas. The first is utilizing and pushing commercially available additive manufacturing technologies. Those technologies include laser metal powder, binder printing and fused deposition modeling.

"This aspect of our work includes producing parts that we actually need and pushing these tools to new places by putting new materials in them, trying to generate new features and doing things people have not done before with these commercially available tools," said Spadaccini, who moderated the panel discussion with LLNL researchers and AM industry experts.

The second area of LLNL's AM work, he said, focuses on using high-performance computing, modeling and simulation to understand the physics of AM processes at a deep level.

"We are trying to model many of the processes we are inventing ourselves as well as commercially available processes," he said. "The most significant of those activities is a very sophisticated model to simulate the laser metal powder fusion process, from powder materials all the way to part performance."

The third area, where Spadaccini does most of his work, is focused on new process development and invention as well as new materials development.

"We are trying to build new additive manufacturing tools," he said. "We are focused on micro- and nanoscale features: How can we make things very small, yet do it over wide areas and in three dimensions? And secondly, we are focused on a mixture of materials -- polymers mixed with metals and ceramics, all in the same component to give radically improved functionality."

LLNL's innovations, some of which are not yet commercially available, are designed to push the envelope in AM research to invent new processes and build materials, Spadaccini said.

"We are controlling the layout in the micro and in some cases, even the nanoscale," he said. "That allows us to control material properties, so we can actually do things like design and fabricate materials with a negative thermal expansion coefficient -- unique properties that don't exist in nature."

The event's panel included Josh Kuntz, LLNL AM material scientist; Bob Ferencz, leader of LLNL's Methods Development Group; Janos Veres, area manager of PARC, a Xerox Company; and Rich Stump; principal of FATHOM, a Bay Area additive manufacturing technology company.

Kuntz said when he started working with AM five years ago, he noticed there was an incredibly narrow set of materials available. He said LLNL has tools and techniques that allow researchers to work with materials such as polymers, particulate polymers, nanoscale metals and ceramics -- blending composites of them together -- to make new materials.

"We do that mostly by creating our own feedstock materials," he said. "That includes the need to control both the size and scale of the particles we are making and the degree of impurities."

Intellectual property bound for industry

The Lab has a lot of intellectual property that it would like to see reach industry and become the next generation of commercially available additive manufacturing tools and materials, Kuntz said.

Ferencz and his research team are using high-performance computing to perform multi-scale modeling of additive manufacturing processes, examining the physical process and its manifestations.

"We are trying to model true parts and configurations," he said. "We want to computationally build a complete part and predict manufactured properties."

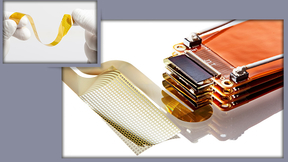

Veres and his PARC research team are combining disruptive material, process and device technologies for printed flexible circuits, sensors and memory arrays and batteries and display devices. Their research is focused on early commercialization opportunities.

"The question is how we can add to additive manufacturing in a way that becomes qualitatively different beyond just shapes and colors," he said. "Electronics is where it starts."

Stump co-founded FATHOM in 2008, the Bay Area's largest 3D printing production center that specializes in 3D printers, rapid prototyping and design. The company has production centers in Oakland and Seattle.

"We are harnessing the [AM] technology for customers in a professional space that utilize it for condensing their product development process," he said. "So we are looking at specific applications - not only conventionally where it's been form, fit, function and prototyping -- but also moving downstream to more manufacturing-based applications."

In April, FATHOM entered into a technology development partnership with Lawrence Livermore tocollaborate on new material development, processing, testing and characterization, as well as application of specific advancements in hardware and software.

Contact

Kenneth K Ma[email protected]

925-423-7602

Related Links

Manufacturing at LLNLLivermore Valley Open Campus

High Performance Computing Innovation Center

Silicon Valley Forum

LLNL Intellectual Property

Tags

Advanced Materials and ManufacturingAdditive manufacturing

Engineering

Featured Articles