Energy Inks wins regional FLC award

(Download Image)

(Download Image)

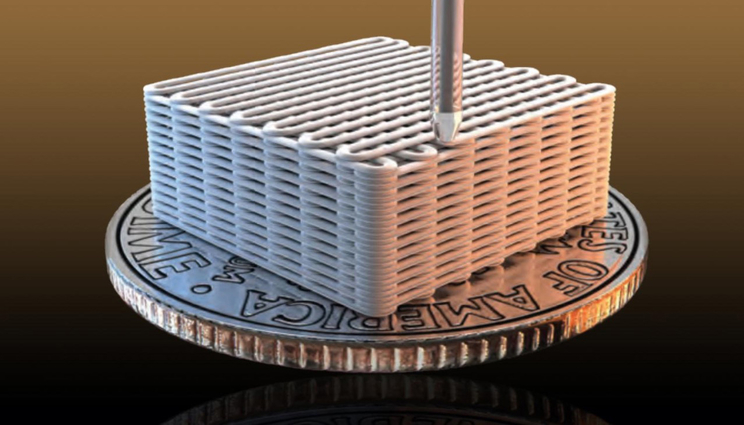

Lawrence Livermore’s precision, direct ink-writing process can print complex architectures used in energy storage devices and other energy-related devices. Shown is a graphic depicting three-dimensional printing with the graphene “energy ink.”

A Lawrence Livermore National Laboratory (LLNL)-developed technology known as Energy Inks has won a best in region award for the Far West region from the Federal Laboratory Consortium for Technology Transfer (FLC).

This is the technology’s second award in the past nine months, as it received an R&D 100 award last September as one of the top 100 industrial inventions in the world.

Developed by a team of Lab scientists and engineers, Energy Inks is a three-dimensional (3D) printer feedstock that allows the production of a functioning battery and other devices.

3D printing with polymers allows a newer and more efficient method of prototyping. With functional properties, Energy Inks are optimized to enable next-generation, high-performance 3D-printed devices for energy storage, catalysis, filtration, sensors and more uses.

Although 3D-printing offers control and reproducibility to efficiently create optimized solid-state electrode architectures on a large scale, the inks required to make functioning components have not been available until now. Energy Inks not only enables the printing of battery and supercapacitor components but optimizes their functional properties.

Since LLNL scientists and engineers developed Energy Inks, they have worked with researchers from the University of California, Santa Cruz and St. Louis-based MilliporeSigma, a global chemical and materials supplier. In 2021, MilliporeSigma introduced Energy Inks products to users for applications in consumer electronics, transportation and medical devices.

Based on LLNL technology, MilliporeSigma has three products — 3D printable graphene oxide ink for batteries, supercapacitors and electrocatalysis; yttria-stabilized zirconium oxide ink for membranes, catalysis and reactors; and ultra-high temperature boron carbide ink for high wear components and heat exchanges.

The LLNL team that developed Energy Inks received funding through a Department of Energy Technology Commercialization Fund grant. It is led by materials scientist Swetha Chandrasekaran and chemical engineer Marcus Worsley. Other LLNL researchers involved in the Energy Inks development are chemists Patrick Campbell, Maira Ceron-Hernandez and Alyssa Troksa, along with materials scientists Josh Kuntz, Wyatt Du Frane and James Cahill.

Researchers from the University of California, Santa Cruz also contributed to developing the graphene ink through electrochemical characterization and demonstration of the ink’s utility as a supercapacitor electrode.

The Energy Inks technology received internal “seed money” from the Laboratory Directed Research and Development program. This funding enables undertaking high-risk, potentially high-payoff projects at the forefront of science and technology.

LLNL researchers are supported by the Lab’s Innovation and Partnerships Office staff, particularly business development executive Genaro Mempin, who oversees the commercialization efforts for Energy Inks, and digital assets coordinator Mary Holden-Sanchez, who manages LLNL’s submission process for technology transfer award programs. LLNL maintains a strong record of winning nominations; since entering the FLC competitions, Lab researchers have won nearly 100 FLC awards.

Headquartered in Sequim, Washington, and started in 1974, the Federal Laboratory Consortium for Technology Transfer (FLC) is the formally chartered, nationwide network of more than 250 federal laboratories, agencies and research centers, that fosters commercialization, best-practice strategies and opportunities for accelerating federal technologies out of the labs and into the marketplace.

Lab materials scientist Swetha Chandrasekaran is shown using a 3D printing process, or direct ink writing, of high concentration graphene oxide ink. After post-processing, free-standing 3D-printed graphene aerogel electrodes are used in supercapacitors that have resulted in record-breaking electric charge storage and “remarkable” energy density. Chandrasekaran and Marcus Worsley led a team of researchers that captured an R&D 100 award. Photo by Julie Russell/LLNL.

Contact

Stephen Wampler

Stephen Wampler

[email protected]

(925) 423-3107

Related Links

Lab Innovation and Partnerships OfficeFederal Laboratory Consortium

Tags

ASCAdvanced Materials and Manufacturing

Materials Science

HPC, Simulation, and Data Science

Computing

Physical and Life Sciences

Industry Collaborations

Technology Transfer

Science

Featured Articles