Electrochemical 'roughening' improves LLNL-developed flexible biological sensors

(Download Image)

Livermore chemist Anna Marie Belle holds a sample case of chemical biosensors she fabricated for measuring neurotransmitters in the brain. Photo by Randy Wong/LLNL

(Download Image)

Livermore chemist Anna Marie Belle holds a sample case of chemical biosensors she fabricated for measuring neurotransmitters in the brain. Photo by Randy Wong/LLNL

Lawrence Livermore National Laboratory (LLNL) engineers and scientists have developed a new technique that enhances the performance of Lab-developed flexible thin-film biological sensors, increasing the sensitivity of the implantable arrays to chemicals for biosensing applications, among other performance improvements.

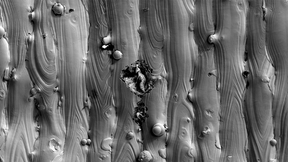

In the latest edition of the Journal of the Electrochemical Society, LLNL researchers report on results achieved by electrochemically "roughening" the Lab-developed platinum multielectrode arrays, which resulted in increased surface area, enhanced capability to record and stimulate cell activity with the electrodes and improved adhesion of metal coatings. By placing the electrode arrays in an electrolyte solution and subjecting them to oxidation-reduction electrical pulses, researchers were able to enhance surface area by 44 times and improve detection of hydrogen peroxide by nearly three times due to greater electron transfer.

Researchers said the increased performance can enable detection of very small neurotransmitter concentrations in the brain or other chemicals of interest in the urine or other bodily fluids, allowing for quicker detection if chemical levels drift out of a healthy range. The research also marks the first time this level of performance enhancement was possible with roughening of thin film electrodes.

"We modified the same process that was used for roughening of foils for decades to roughen thin film electrodes that are much more delicate in nature. The process is complex because it involves absorption, diffusion, surface reconstruction and multiple stages of oxidation. We achieved roughening of thin films by fine-tuning control parameters," said the paper’s lead author Anna Ivanovskaya, an LLNL electrochemist and nanofabrication engineer. "Increasing the surface area of devices is great because it allows us to create better properties of the interface between the tissue and device and optimize the sensor signals."

The roughening process uses a weakly adsorbing electrolyte that enables reactivity of the grains, rather than selectively dissolving grain boundaries of the platinum, and then redeposits platinum grains instead of wearing them away. This allows for more surface of the electrodes to interact with tissue for improved recording and stimulating of electrical signals in the brain, better biosensing performance and adhesion of metal coatings of the implantable devices necessary for chemical sensing, such as platinum-iridium. The researchers said the enhancements are critical for the advancement of neural interfaces for animals and eventually humans, as electrodes further miniaturize.

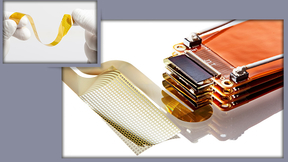

"You’re not increasing the actual footprint of the device, but as you get smaller and smaller you need more interface with the tissue and this micro-roughening makes that happen," said LLNL researcher Anna Belle, whose work focuses on sensor development. "We can still make these high-density microarrays, but also get the performance as if the electrodes were bigger."

Belle added that the new roughening approach also is improving the performance and robustness of chemical sensors researchers are integrating onto the Lab’s multi-electrode arrays. "For a lot of the sensor coatings we now use roughening to improve performance," Belle said. "The roughened electrode acts like Velcro, so if you were to put something on top of it, it sticks better than if it were a smooth surface. This is one of those improvements that allows us to make the quality devices that people expect, but also continue pushing to make the electrodes even smaller."

LLNL and its partners have used the Lab’s patented thin-film multi-electrode arrays in numerous projects in the past, including artificial retinas, cochlear implants and neural implant work for the Defense Advanced Research Projects Agency and the University of California San Francisco. The teams’ roughening technique is being incorporated into certain versions of the Lab’s neural arrays, improving chemical sensing, electrical recording and stimulating electrical signals. Researchers hope the improved electrodes will be incorporated into sensor platforms for other biomedical applications, such as bedside diagnostics for sepsis.

Other LLNL scientists who contributed to the research include Allison Yorita, Fang Qian and Angela Tooker, as well as past Lab summer interns Rose Garcia Lozada and Dylan Dahlquist. Former LLNL engineers Vanessa Tolosa and Supin Chen also are named as co-authors.

The Laboratory Directed Research and Development (LDRD) program funded the work.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Neurotech at LLNL"Research by Lawerence Livermore scientists may help validate organ-on-a-chip devices"

"LLNL-developed microelectrodes enable automated sorting of neural signals"

Journal of the Electrochemical Society

Tags

EngineeringFeatured Articles