Determining structural evolution under pressure

(Download Image)

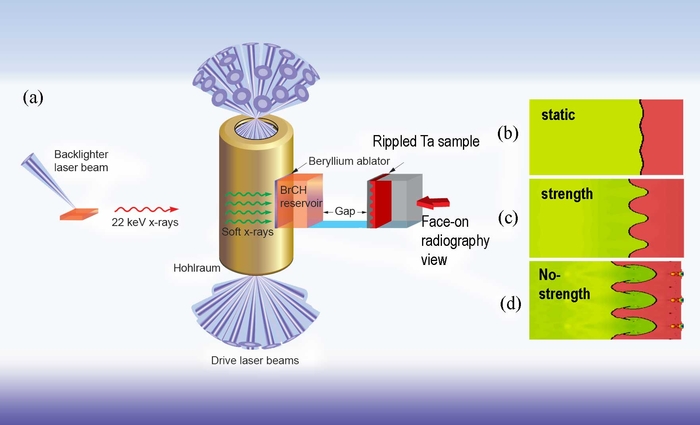

In this experimental setup at the Omega Laser Facility, the hohlraum drives the reservoir-gap configuration, creating a ramped plasma drive that compresses and accelerates the sample without shock melting. The team measured the Rayleigh-Taylor instability ripple growth amount to infer the dynamic flow stress of the sample.

(Download Image)

In this experimental setup at the Omega Laser Facility, the hohlraum drives the reservoir-gap configuration, creating a ramped plasma drive that compresses and accelerates the sample without shock melting. The team measured the Rayleigh-Taylor instability ripple growth amount to infer the dynamic flow stress of the sample.

The study of material properties under the conditions of extreme high pressures and strain rates is important for understanding meteor, asteroid or comet impacts, as well as in hypervelocity impact engineering, inertial confinement fusion (ICF) capsules, and basic high energy density (HED) physics. In a recent study published by Physical Review Letters, a team of LLNL scientists report a key finding that can be used to determine the evolution of structures under high pressure and strain rates.

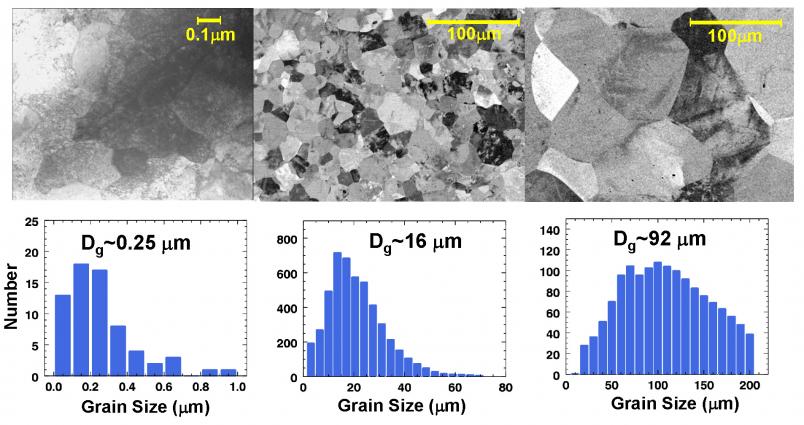

The paper details experimental results on the grain-size dependence of plastic flow stress (that is, resistance to plastic deformation) under high pressure (>100 GPa) and high strain rates (>107s-1). Higher flow stress means that the material is less prone to deform in the presence of an applied force. Under quasi-static conditions, smaller grain-sized materials are stronger. This observation is known as the Hall-Petch (H-P) relation and is used in industry to increase hardness, durability, and survivability of structural materials. It was not known, however, if the H-P relation holds under high pressure and high strain-rate conditions such as in hypervelocity impacts or ICF conditions.

"Measuring material flow stress at high pressures and strain rates without melting is a formidable task," said lead author Hye-Sook Park. "We designed an experimental platform to drive samples to high pressures without melting using a laser-generated plasma piston drive."

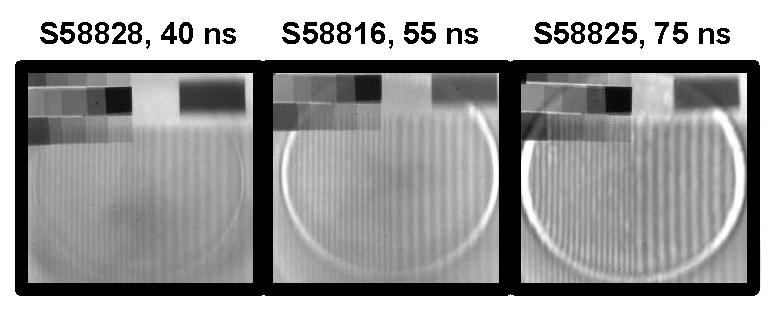

The strength of a sample material is inferred by obtaining a radiograph of the Rayleigh-Taylor (RT) instability induced growth of ripples machined into the surface. Low-strength materials have little resistance to plastic (irreversible) deformation and the ripples grow rapidly due to the RT instability. In high-strength materials, ripple growth is suppressed. The measured amount of RT-induced ripple growth is used to infer the strength.

The team completed a series of experiments at the University of Rochester’s OMEGA Laser Facility. Measurements showed that flow stress is insensitive to grain size at the high strain rates of these laser experiments, whereas the H-P theory predicted an increase in strength of at least a factor of two under quasi-static conditions for these samples.

"There are many surprises to be found in nature under the extreme conditions that we call the high energy density regime, and exploring material properties under these conditions has been challenging," Park said. "Laser experiments provide a unique way for us to study this regime. The material dynamics under these HED conditions differ significantly from those under quasi-static conditions."

The experiments studied materials at pressures of 100 GPa. Plans are now underway to extend the study to pressures of 500 GPa or higher at NIF and to include nano-grain samples (<30 nm in diameter) and samples including high pressure phase transitions.

"We expect that many more exciting discoveries will emerge in this area in future experiments on OMEGA and NIF," Park said.

Co-authors on this paper include Hye-Sook Park, Rob Rudd, Rob Cavallo, Nathan Barton, Tom Arsenlis, Jon Belof, Kerri Blobaum, Bassem El-dahser, Jeff Florando, Channing Huntington, Brian Maddox, Mark May, Chris Plechaty, Shon Prisbrey, Bruce Remington, Russ Wallace, Chris Wehrenberg and Mike Wilson from LLNL; Andrew Comley of the Atomic Weapons Establishment; Emilio Giraldez, Abbas Nikroo, Mike Farrell and Greg Randall of General Atomics; and Rusty Gray of Los Alamos National Laboratory.

Contact

Breanna Bishop

Breanna Bishop

[email protected]

(925) 423-9802

Related Links

National Ignition FacilityPhysical Review Letters

Tags

Lasers and Optical S&TLasers

National Ignition Facility and Photon Science

Featured Articles