Crash-proof virtual flying through NIF

(Download Image)

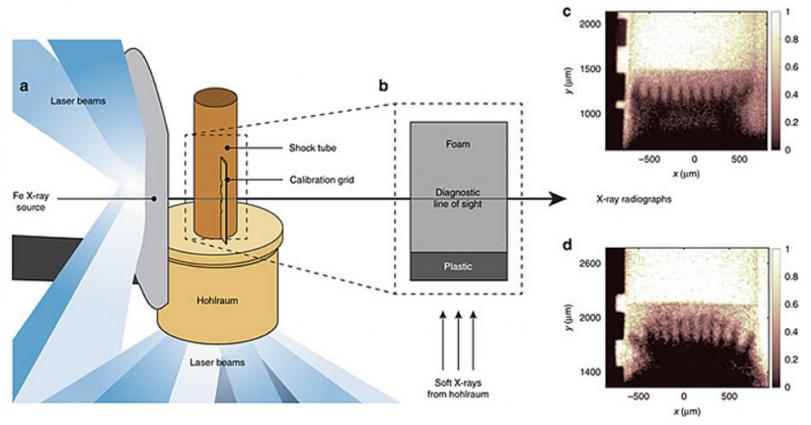

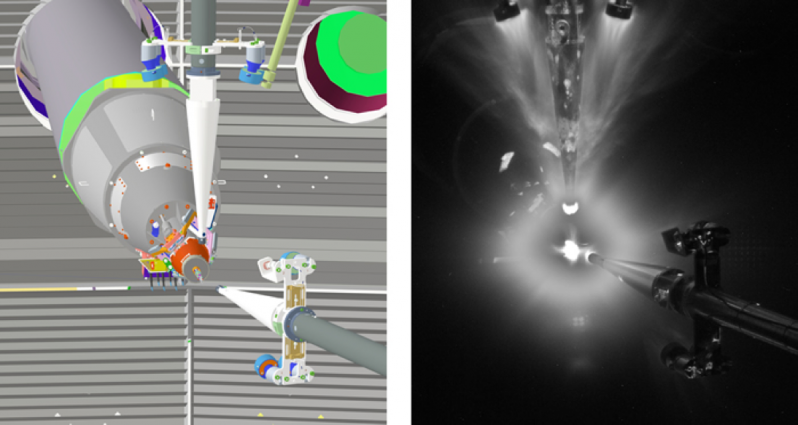

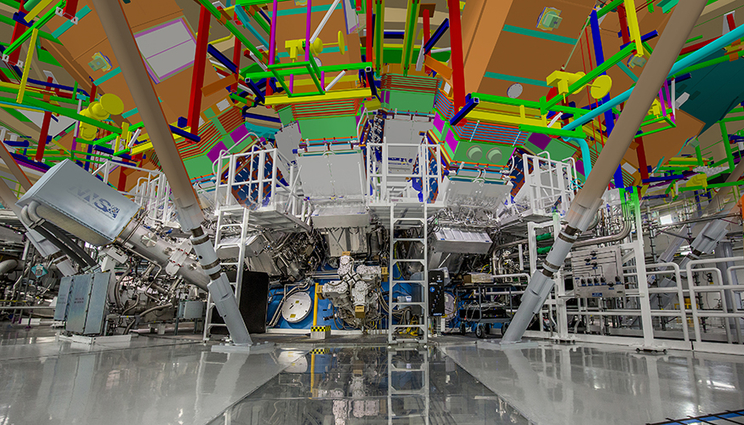

A virtual-reality rendering of the upper portion of the NIF Target Chamber exterior blended with a photo of the lower portion. By using realistic graphics designed with the aid of virtual reality programs by design engineer Paul Bloom, NIF researchers can efficiently navigate the facility and plan their experiments to maximize scientific results. Composite graphic credit: Brian Chavez

(Download Image)

A virtual-reality rendering of the upper portion of the NIF Target Chamber exterior blended with a photo of the lower portion. By using realistic graphics designed with the aid of virtual reality programs by design engineer Paul Bloom, NIF researchers can efficiently navigate the facility and plan their experiments to maximize scientific results. Composite graphic credit: Brian Chavez

In apparent defiance of the laws of physics, LLNL design engineer Paul Bloom leads flying tours through the National Ignition Facility from only three feet off the ground.

As creator of the NIF virtual reality (VR) program, Bloom routinely allows engineers, scientists and technicians to soar through the facility by plugging his NIF tourists into special 3D Model Visualization portal headsets and his supercharged computer. Swooping them through the laser beampath at up to 100d meters per second, he has turned NIF mechanical design on its head with his VR tools.

Bloom has spent the last 20 years customizing his unique program by blending standard 3D engineering CAD (computer-aided design) programs and maturing virtual reality software to meet the needs of his NIF & Photon Science colleagues.

"Not only is it supporting science, it’s about discovery and pushing the boundaries into new realms," he says. "This kind of design engineering work is fun for me, which helps with the learning curve."

Bloom flies engineers like Robin Hibbard virtually anywhere in the facility, from anterooms and exteriors to the heart of the target chamber, zooming close enough to touch without risk to humans or machinery. Hibbard, who finds Bloom’s VR invaluable for effective diagnostics placement planning, says, "You use something that’s not real to find out something that’s real."

The Lab’s Mark Bowers, Laser Systems section leader, optical systems project associate manager, taps Bloom extensively to perform engineering modeling for his group’s installations without having to shut NIF down for prolonged periods. "You can look at a drawing all day long," Bowers says, "but you’re not going to see it really unless it’s in full dimension. This 3D immersive VR is even better because you can see through structures and inside and around in dense areas."

On a recent visit to Bloom’s 3D model studio across the road from NIF, Bowers straps on the black gleaming VR headset and dives into the NIF virtual structures like meeting up with old friends, as Bloom follows his progress from the computer across the room.

"Oh, there’s Dante (a key NIF diagnostic)," Bowers says. "There’s DIXI (the world’s fastest X-ray camera)…I’m riding up to the target now…Now we’ve got stuff going on…There’s the cryo (target positioner)…I believe that’s where Capt. Kirk died in ‘Star Trek’… (NIF was the setting for the 2013 film "Star Trek: Into Darkness").

After updating himself on what’s new in the virtual NIF, Bowers turns in his headset and calls out a long list of his team’s projects that benefited from VR pre-review, including the time he needed the measurement for an area in NIF under a vacuum seal and open only a few times a year. Another advantage of Bloom’s VR tours is that personnel can "get inside" to be more prepared when the area opens, saving time, costs and stumbles, says Bowers.

For example, NIF technicians only get an opportunity to enter the target chamber once a year, and only for a couple of days. In order to make the most efficient use of this time, they "practice" critical operations using the VR system in order to tune up their procedures and equipment. This saves both time and money by keeping the target chamber entry activities on schedule.

At NIF, Bloom has used many different software and CAD programs over the years and currently utilizes Virtalis software from a U.K.-based company that combines computer projectors and headsets resembling night-vision goggles. It ushers viewers into a private VR universe where theyfeel like they can walk through walls. To help simulate some of that NIF ambiance, NIF’s Document Services team papered the Model Visualization studio walls with colorful wall-to-ceiling photographs of the target chamber.

Making solid structures transparent

Recently, he installed diagnostic hardware in the complex and crowded space, because unlike standard 3D engineering software, his programs can see through solid structures. He’s helped determine how to install precision equipment and advised the transport and handling team on a verified transport path requiring minimal moving of existing equipment, saving time and costs.

In the physical world, the technology of virtual reality can come as a jolt because objects sometimes seem to disobey the laws of physics. One of the issues involving flying at high speeds is the reaction that people can have to the experience of immersion, Bloom acknowledges, what’s sometimes called sensory conflict theory, aka motion sickness.

Some scientists and technical staff using the VR program prefer the standard non-immersive review, with Bloom flying them through the 3D model and the moving model image projected on a large screen. This makes it easy to interact with a group, capture screenshots, and take measurements. He also uses the VR program for training technicians, engineers and scientists, along with real-time problem-solving capability.

Steve Mills, the NIF design integration supervisor, is a big fan of Bloom’s VR program because of the way it simulates areas otherwise difficult to reach. "People have been satisfied in the past with just using a monitor and the CAD programs," says Mills. "Having Paul in that role has been fantastic, because he’s always looking out on the cutting edge of the technology and bringing it to us."

Hibbard, the project engineer in NIF target diagnostics, finds what is useful about Bloom’s VR program is putting himself in the target bay, virtually, and thinking about a new diagnostic. "You can fly around the building and see available space if you’re building something near the target chamber," he says. "It’s a good tool to see how you’re going to solve a problem."

For example, when Hibbard was working on a new polar nuclear imaging system, he looked at options for locating a new nuclear imaging line-of-sight diagnostic and decided that he had to adjust the angle through the port to get a line of sight without difficult structural steel interference. Nuclear imaging looks at the shape of the compression of target capsules based on the generation of neutrons late in time, in the last half of the implosion. "We looked for a line of sight for a detector that would potentially make use of existing target building wall penetrations while avoiding surrounding hardware, yet still achieve the desired physics outcome," he says.

Bloom has worked successfully with many other scientists and engineers, including Jonathan Fry, Sky Marshall, Matt Fischer and Justin Galbraith, exploring the versatility of the virtual reality program and expanding its capabilities. Recent projects have involved providing laser light ray-trace and shadow-casting within the NIF model, animating systems to simulate operating hardware motion, and creating model animations for diagnostic motions and clearances for the transport and handling team.

On a recent Tuesday morning, LLNL physicist Rich Zacharias came in to talk about the VR potential for target design. The project he proposed was to bring detailed target models and laser-beam aiming models together in the virtual world, allowing the reviewer in the headset to control the scaling of the models or the magnification of the view in order to understand the interaction of target components and laser beams.

"I’m really excited," Bloom says, "because it opens a whole new realm for me."

-Lisa Petrillo

Contact

Breanna Bishop

Breanna Bishop

[email protected]

(925) 423-9802

Related Links

Lasers at LLNLTags

Lasers and Optical S&TLasers

National Ignition Facility and Photon Science

Featured Articles