3D printing could revolutionize laser design

(Download Image)

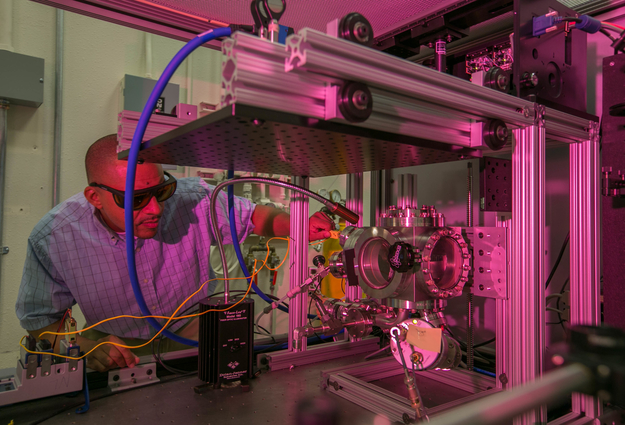

Ibo Matthews inspects an in situ diagnostics test bench his team developed for studying laser-driven powder bed fusion additive manufacturing. High-speed thermal and optical mapping of the laser-powder interaction has enabled the team to reveal new physics associated with the process and helped guide high-performance computing simulations. Photo by Julie Russell.

(Download Image)

Ibo Matthews inspects an in situ diagnostics test bench his team developed for studying laser-driven powder bed fusion additive manufacturing. High-speed thermal and optical mapping of the laser-powder interaction has enabled the team to reveal new physics associated with the process and helped guide high-performance computing simulations. Photo by Julie Russell.

LLNL researchers are exploring the use of metal 3D printing to create strong, lightweight structures for advanced laser systems - an effort they say could alter the way lasers are designed in the future.

In a Laboratory Directed Research and Development (LDRD) program, physicist Ibo Matthews and his team are experimenting with a new research-based metal 3D printer, one of only four of its kind in the world, using a customized software platform capable of unprecedented design control.

The powder bed laser-melting printer, made by the Fraunhofer Institute for Laser Technology (ILT) and German startup Aconity 3D, was installed in December 2015. Lab engineers have added diagnostics and high-speed cameras to examine thermal emissions and to image the surface of parts as they’re being built. Matthews said the modifications will help the researchers determine how defects or deformations occur during the 3D printing process.

"It’s very flexible; it allows us to change any of the parameters we want," he said. "We’re developing confidence in what we’ve built. If any defects occur, it is our aim that the user can have a 3D map available at the end of the build that shows what and where it happened."

Matthews and his team are building on their experience in laser materials processing and interaction gained in support of both the National Ignition Facility (NIF) and directed energy projects to develop new approaches to metal 3D printing. Their work is part of an overall strategy to broaden the NIF & Photon Science (NIF&PS) laser applications portfolio and maintain core competencies in laser-matter interaction science. Moreover, NIF scientists are intrigued by the potential for the metal 3D printing platform to support lasers - not just at NIF, but in airborne systems that need to be extremely lightweight, such as those used for remote sensing and aerial scanning.

"With precision, predictive control of 3D printing you can put the stiffness where you need it," said Mike Carter, NIF&PS program director for Department of Defense Technologies. "You can create functionally graded structures for optical lasers and mounts that are impossible to make by conventional manufacturing methods."

NIF has utilized some metal parts printed at the Lab in structures for lasers. In order to use them in critical systems on a regular basis, however, researchers must be assured that each part is sound.

To speed up the certification process, Lab engineers are attempting to shorten the development phase by taking a completely different approach - a "feed-forward" method based on computer modeling instead of trial and error. If successful, said Wayne King of LLNL’s Physical and Life Sciences Directorate, the research could fundamentally change the way metal components - including those used in optical systems - are designed and fabricated.

"Unless you take a science-based approach to this, you won’t know why part A is different from part B," King said. "We’re really pushing the state of the art. We’re at the beginning of seeing some applications of the technology already."

In the three-year LDRD project that began last year, Matthews and his team will be combining metal 3D printing with both high-fidelity optical diagnostics and high-performance computing to create more confidence in the parts they create.

"What we’d like to do is drive this process based on simulation, and create a ‘digital fingerprint’ of certification based on optical monitoring to ensure the part is built right the first time," Matthews said. "We’d like to be predictive, based on our physics models, to find out what we can expect with any given build and have monitoring data to show that predictions matched the outcome."

Matthews added that the Lab’s newest machine will go a long way toward discovering the capabilities and application of metal 3D printing for laser design.

"It takes you from this black box to something you have control over," he said. "It puts us two years ahead of where we would’ve been if we hadn’t bought it."

NIF&PS and the Lab’s Weapons and Complex Integration and Engineering directorates are jointly supporting the new printing platform.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Denudation of metal powder layers in laser powder bed fusion processesNational Ignition Facility

Tags

EngineeringFeatured Articles